Sustainable Water Infrastructure Contacts

Pacific Southwest, Region 9

Serving: Arizona, California, Hawaii, Nevada, Pacific Islands, Tribal Nations

Water & Energy Efficiency in Water and Wastewater Facilities

| Sustainable Water Infrastructure Quick Finder | ||||

|---|---|---|---|---|

| FundingGreen Jobs in the Water SectorLow Impact Development | Waste To Biogas Mapping ToolWater Conservation/EfficiencyWater-Energy Connection | Water Loss ControlWhy Sustainability? | ||

Energy Efficient Equipment, Technology and Operating Strategies

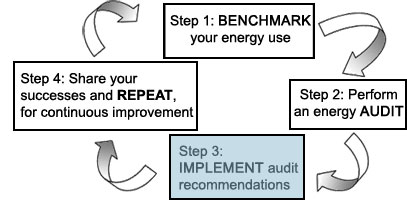

The audit results are in and there are a number of changes, large and small, that can be made to save on energy costs. Facilities have many options to conserve energy ranging from changing light bulbs and upgrading pumps and motors to installing co-generation systems and renewable energy technologies. We've highlighted many of these energy saving options below and provided case studies to show you how some facilities have used these equipment, technology and operating strategies to save money and reduce their impact. Additionally, the California Energy Commission provides information on a range of energy efficient technologies. ![]()

You will need Adobe Reader to view some of the files on this page. See EPA's PDF page to learn more about PDF, and for a link to the free Adobe Reader.

On this page:

- Equipment & Collection System Upgrades

- Operating Strategies

- Energy Efficient Technology

- Renewable Energy

Water Environment Research Foundation's Decentralized Systems Performance and Costs Fact Sheets ![]()

Equipment and Collection System Upgrades

Install Variable-Frequency Drives

A variable-frequency drive is an electronic controller that adjusts the speed of an electric motor by modulating the power being delivered. These drives provide continuous control, matching motor speed to the specific energy demands needed. A variable-frequency drive can be a significant cost-saving device for water and wastewater facilities.

- The California Energy Commission explains further in this variable-frequency drive fact sheet (PDF) (2 pp, 55K)

- East Bay Municipal Utility District's energy efficient upgrades included variable-frequency drives (PDF) (2 pp, 1.1MB)

- Encina, California installed variable-frequency drives (PDF) (3 pp, 32K)

Upgrade to Energy Efficient Motors and Motor Systems

As a regular part of plant maintenance new motors and motor systems are installed as old ones wear out. Upgrading to energy efficient motors can save energy, reduce maintenance costs, and protect the environment. The Consortium for Energy Efficiency's (CEE) Municipal Water and Wastewater Initiative (PDF) (15 pp, 111K) ![]() promotes energy efficiency at the facility level. CEE developed the Water and Wastewater Facility Initiative Template located on page 5 of the initiative description. This template provides information on a variety of energy conservation measures from simple motor change-outs to more complex process improvements.

promotes energy efficiency at the facility level. CEE developed the Water and Wastewater Facility Initiative Template located on page 5 of the initiative description. This template provides information on a variety of energy conservation measures from simple motor change-outs to more complex process improvements.

- Inland Empire Utilities Agency's Ontario facility upgraded their pumps and motors and annually saves $57,000 in energy costs; $14,000 in maintenance costs; and 475,000 kWh.

Heating, Cooling, Ventilation System Upgrades

Water and wastewater facilities can upgrade their heating, cooling, and ventilation systems to improve energy efficiency and save money while keeping the work environment comfortable. The California Energy Commission has provided strategies for water and wastewater facilities (PDF) (2 pp, 13K) ![]() to increase the energy efficiency in their buildings.

to increase the energy efficiency in their buildings.

Bright Lights Bring Energy Savings

Water and wastewater facilities can also save costs by installing energy efficient lights and lighting systems. There are two types of energy efficient lighting--advanced florescent lighting for indoor lighting and high density discharge lighting for outdoors. A facility can also use lighting controls such as occupancy sensors, time switches, and dimming systems to save energy. The California Energy Commission has provided suggestions on how a facility can save energy and costs with improved lighting. ![]()

Operating Strategies

Managing Your Electrical Load

Energy efficient strategies for managing electrical load can bring significant cost savings. Such strategies include reducing peak demand, shifting to off-peak hours, and improving the power factors of motors. The California Energy Commission describes electric utility billing rates and suggests energy-saving strategies (PDF) (3 pp, 42K).

- Southern California's Moulton Niguel Water District installed logic controllers to benefit from off-peak utility rates (PDF) (3 pp, 61K).

- Phoenix, Arizona water and wastewater facilities benefit from reducing peak demand.

Biosolids Management

Biosolids are the solid organic matter derived from the sewage treatment process. Sustainable biosolids treatment, transport, and end-use can reduce economic and environmental costs. Communities throughout Region 9 are managing sludge in innovative ways, reducing on-site emissions and truck miles, saving money, and generating energy.

In the San Francisco Bay Area, sixteen Bay Area agencies formed the Bay Area Biosolids to Energy coalition ![]() to create a local sustainable solution to biosolids management by utilizing the remaining energy.

to create a local sustainable solution to biosolids management by utilizing the remaining energy.

In San Diego, the Encina Wastewater Authority manages biosolids with a two tier management plan (PDF) (2 pp, 877K): The "tier one" approach prioritizes short term uses – such as biofuel generation and landfill application. The "tier two" approach directs biosolids towards uses that require more development, that are seasonal, and incorporate other markets – such as recreational fields and/or orchards.

For more information on the value of biosolids management and applications, review the Water Environment Federation webcasts ![]() .

.

Operation and Maintenance

Changing pumps, motors, and lighting is a good start toward improving energy efficiency. What is equally important is changing the mindset and attitudes of facility managers and staff. Training managers and staff on the importance of energy efficient practices is key to successfully implementing energy conservation at your facility. Practices such as turning off lights when not needed, timing maximum energy use for off-peak hours, reducing the use of oxygen, and looking for other opportunities to increase energy conservation at the facility will improve your bottom line and the environment.

Inflow and Infiltration Control

Inflow and infiltration in a facility's collection system is costly for a wastewater treatment facility. Increased flow in the system results in higher operational and capital costs. Energy costs are associated with processing and sorting the additional flow, and sewer lift stations need to pump continuously. The system runs the risk of overflows as it becomes overloaded. Inflow and infiltration problems can result in millions of gallons per day of increased flow into the wastewater facility, necessitating increased discharges of treated effluent to the receiving stream. EPA has suggestions for reducing inflow in its Combined Sewer Overflow Technology Fact Sheet: Inflow Reduction (PDF) (7 pp, 71K) .

Case Study: Johnson County, Kansas

In 1985, Johnson County Wastewater implemented a dual inspection program. Concurrent with their collection system evaluation, they went house-to-house and business-to-business, inspecting private connections in more than 55,000 structures. The surveys resulted in the repair or replacement of 17,000 manhole structures, and disconnection of more than 15,600 unpermitted sources of storm water inflow on private property.

Case Study: Greenwood, South Carolina

For the Greenwood Metropolitan District, a good Comprehensive Management, Operations, and Maintenance Plan (PDF) (1 pp, 323K)

was more than a way to abate sanitary sewer overflows, it was also a way to bring community leaders to consensus on difficult, expensive infrastructure problems.

For other case studies on controlling inflow and infiltration go to EPA's NPDES Case Studies site.

Energy Efficient Technology

Cogeneration or Combined Heat and Power

Cogeneration

Combined heat and power (CHP), also known as cogeneration, is an efficient, clean, and reliable approach to generating power and thermal energy from a single fuel source. Wastewater treatment facilities that have anaerobic digesters create methane gas as a by-product of digestion of biosolids. Currently, a number of these facilities release methane gas by flaring, converting methane to CO2 and releasing it into the environment. Methane gas, however, is a good source of energy. By installing a CHP system designed to meet the thermal and electrical base loads of a facility, CHP can greatly increase the facility's operational efficiency and decrease energy costs. At the same time, CHP reduces the emission of greenhouse gases, which contribute to global climate change.

Producing your own electricity on-site has significant advantages. CHP systems have economic and environmental benefits including reduced energy costs, offset of capital costs, protected revenue streams, hedge against volatile energy prices, and reduced reliance on outside energy sources. CHP technologies include turbines, microturbines, internal combustion/reciprocating engines, steam engines/turbines, and fuel cells.

There are a number of wastewater treatment facilities that have installed cogeneration or combined heat and power. Excess methane can be captured and may be accepted by local power companies. Using the gas directly instead of converting it to electricity is an efficient application because energy is lost each time it is converted or transmitted over long distances.

Tucson, Arizona

- The Ina Road Water Pollution Control Facility (PDF) (2 pp, 247K)

achieved an annual savings of $1.26M from installing a cogeneration system.

achieved an annual savings of $1.26M from installing a cogeneration system.

Corona, California

- The Clearwater Cogeneration Wastewater Treatment Facility

installed a cogeneration system that supplies heat back to the digesters and provides power to the local power utility.

installed a cogeneration system that supplies heat back to the digesters and provides power to the local power utility.

Oakland, California

- The East Bay Municipal Utility District (PDF) (3 pp, 52K)

saves $200,000 - $300,000 annually with an expected payback period of 6-8 years.

saves $200,000 - $300,000 annually with an expected payback period of 6-8 years.

Cogeneration Using Landfill Gas

Some wastewater treatment facilities with anaerobic digesters located close to landfills harness the methane gas from the landfill and combine it with methane from their anaerobic digesters to provide additional power for their facility.

San Diego, California

- The Metropolitan Wastewater Department

is an example of cogeneration using landfill gas. Methane is a by-product produced in the digesters at the Metro Biosolids Center (MBC), and in the adjacent Miramar Landfill. Methane produced by the MBC on-site digesters and from the adjacent landfill is converted to electricity which is used to run the facility. Thermal energy produced by the generators is used to heat the MBC, as well as air condition the facility through a process called absorption chilling.

is an example of cogeneration using landfill gas. Methane is a by-product produced in the digesters at the Metro Biosolids Center (MBC), and in the adjacent Miramar Landfill. Methane produced by the MBC on-site digesters and from the adjacent landfill is converted to electricity which is used to run the facility. Thermal energy produced by the generators is used to heat the MBC, as well as air condition the facility through a process called absorption chilling.

San Jose, California

- San Jose/Santa Clara Water Pollution Control Plant. Located at the southern shore of the San Francisco Bay, the San Jose/Santa Clara Water Pollution Control Plant (Plant) is the largest advanced (tertiary) facility on the West Coast. It serves 1.4 million people and 16,000 businesses across eight cities. Built in 1956 and expanded twice, the Plant has been generating electricity with internal combustion engines since its inception. Currently, Plant operations require about 10.8MW daily. Of this amount, the Plant generates about 5.6MW of electricity and 3MW equivalent of compressed process-air by running 6 internal combustion engines and three engine-driven compressors on a blend of two-thirds biogas (produced in roughly equal amounts from onsite digesters and the adjacent Newby Island landfill) and one third purchased natural gas. This total of 8.6MW offsets, on average, 75 percent of the Plant’s electricity needs. All of the Plant’s digester-produced biogas is used by the engines, and in turn, the waste heat from the engines is used to heat the digesters and several support buildings. The Plant’s estimated annual cost savings by using renewable digester and landfill gas is approximately $4 million. Through process improvements that enhance methane production and developing other green energy sources, including a 1.4 MW fuel cell now in operation, Plant officials anticipate that the facility will become energy self-sufficient by 2022.

Renewable Energy

In Conduit Hydro-Power

In conduit hydropower refers to the generation of hydroelectric power in existing tunnels, canals, pipelines, aqueducts, flumes, ditches or similar man-made water conveyances that have been equipped with electric generating equipment. Several Region 9 entities have installed In conduit hydropower units, including the San Diego County Water Authority (CA), Eastern Municipal Water District (CA), and City of Prescott (AZ).

San Diego, California

San Diego County Water Authority ![]() installed a 4.5MW generator at its Ranchos Penasquitos Pressure Control Hydroelectric Facility (RP PCHF). The project can provide enough power for approximately 5,000 households in the area. The San Diego County Water Authority signed a long-term agreement to sell the facility’s power to utility SDG&E; it expects to be able to pay back the cost of installing the hydroelectric project in seven years.

installed a 4.5MW generator at its Ranchos Penasquitos Pressure Control Hydroelectric Facility (RP PCHF). The project can provide enough power for approximately 5,000 households in the area. The San Diego County Water Authority signed a long-term agreement to sell the facility’s power to utility SDG&E; it expects to be able to pay back the cost of installing the hydroelectric project in seven years.

Solar Power

Harnessing the sun's energy using solar technologies can be a reliable source of energy for water and wastewater facilities in some parts of the country, especially in Region 9. The energy in sunlight striking the earth for 40 minutes is equivalent to global energy consumption for a year. At least 250,000 square miles of land in the Southwest alone is suitable for constructing solar power plants. Solar technologies diversify our energy supply, reduce our dependence on imported fuels and the demand for other fuels, improve air quality, and offset greenhouse gas emissions.

The U.S. Department of Energy lists three types of solar technologies: concentrating solar power, photovoltaics, and solar heat. Concentrating solar power systems use reflective materials that concentrate the sun's heat energy to drive a generator that produces electricity. Photovoltaic systems use semiconductor materials that convert sunlight directly to electricity. Solar heating consists of solar collectors that absorb the sun's energy to provide low-temperature heat used directly for hot water or space for buildings. The Solar Energy Technologies Program ![]() Web site provides more detailed information on each type of solar technology.

Web site provides more detailed information on each type of solar technology.

States in Region 9 have the highest potential for harnessing solar radiation ![]() as an energy source. In fact, the first wastewater treatment facility to be powered by solar energy

as an energy source. In fact, the first wastewater treatment facility to be powered by solar energy ![]() in the United States is in Oroville, California.

in the United States is in Oroville, California.

Wind Power

Wind can be a powerful source of energy in some areas of the country. An area that has a relatively constant, steady wind supply may provide the conditions necessary for generating wind power. Explore the links below to see whether wind power is a viable option for you.

Wastewater facilities in Browning, Montana ![]() and Farmington, Maine are harnessing wind power. Each wastewater treatment facility installed wind turbines to generate electricity.

and Farmington, Maine are harnessing wind power. Each wastewater treatment facility installed wind turbines to generate electricity.

Biodiesel Production

Biodiesel is an alternative fuel produced from renewable resources such as virgin oils (soybean, canola, palm), waste cooking oil, or other biowaste feedstock. Biodiesel significantly reduces asthma-causing soot, greenhouse gases, and sulfur dioxide in air emissions. Along with creating less pollution, biodiesel is simple to use, biodegradable and nontoxic. When produced from post-consumer resources such as used fats, oil and grease (FOG) this process recovers energy and recycles waste oils that are either dumped in landfills or flushed down drains, clogging pipes and causing costly sewer over flow spills.

FOGs accumulate and can clog pipes and pumps both in the public sewer lines as well as in wastewater treatment facilities. Why clog pipes and pumps when you can become more energy efficient by converting the fats, oils, and grease to biodiesel? Some wastewater treatment facilities in California are taking this energy conservation idea one step further and anticipate collecting additional fats, oils, food waste, and grease from restaurants/schools/hospitals/prisons to produce even more biodiesel! (For an explanation of biodiesel production, see EPA's Biodiesel Web site.)

Why would a wastewater treatment facility want to do this? There are several reasons:

- The price of petroleum diesel makes converting free readily available fats, oils, grease, and other biofeedstock to biodiesel economically very attractive.

- Wastewater treatment plants are ideal sites for biodiesel generation, because supply and demand for this alternative fuel are at the same location.

- If FOG or "brown grease" becomes a commodity, it assumes market value and less gets dumped down the drain. This source reduction process will save utilities millions of dollars, e.g. , the city of Los Angeles has over 2,000 sewer spills in a year, the majority caused by FOG.

- Fats, oil and grease collections going to POTWs could create an income from the waste hauling tipping fees.

- The wastewater treatment facility may be able to sell the excess diesel on the market.

- The wastewater treatment facility has the footprint, permitting and siting advantages to install equipment to create biodiesel.

- Biodiesel produced onsite can power back up generators for peak shaving purposes to save electricity costs.

Some examples of wastewater treatment facilities investigating biodiesel production include:

- Pacifica, California

The Pacifica Wastewater Treatment Facility is installing a biodiesel production facility to run at their Calera Creek Wastewater Plant. The facility will convert fryer oil collected from restaurants throughout the Bay Area into biodiesel. The biodiesel will power the wastewater facility's generators at peak hours and the city's own fleet of diesel vehicles. The air emissions from the generators will be routed through the POTW system to reduce NOx emissions. Energy costs may be reduced by up to $60,000 a year.

The biodiesel will power the wastewater facility's generators at peak hours and the city's own fleet of diesel vehicles. The air emissions from the generators will be routed through the POTW system to reduce NOx emissions. Energy costs may be reduced by up to $60,000 a year. - San Francisco, California

The San Francisco Public Utility Commission (SFPUC) is committed to cleaning up San Francisco's sewer system and converting waste products into fuels by collecting grease for free in the city. This biodiesel project is part of the largest commitment to biodiesel ever made by a major American city. The whole city fleet runs on biodiesel including fire trucks, airport, and public transit. The Oceanside Sewage Treatment Facility has received $1M in grant funds from the California Energy Commission to construct a biodiesel facility at its plant. San Francisco hopes this project will be a model for other POTWs.

by collecting grease for free in the city. This biodiesel project is part of the largest commitment to biodiesel ever made by a major American city. The whole city fleet runs on biodiesel including fire trucks, airport, and public transit. The Oceanside Sewage Treatment Facility has received $1M in grant funds from the California Energy Commission to construct a biodiesel facility at its plant. San Francisco hopes this project will be a model for other POTWs. - Perris, California

Eastern Municipal Water District (EMWD) is the 5th largest water district in California. EMWD is exploring a source reduction project to convert grease from haulers and the plant into biodiesel. The district is working with grease haulers in Western Riverside County to convert brown grease into a renewable and environmentally friendly fuel. The goal of this source reduction project is to convert 5 million gallons of fats, oils and grease into 250K gallons of B100. The expected cost for the test program is $250K.

project to convert grease from haulers and the plant into biodiesel. The district is working with grease haulers in Western Riverside County to convert brown grease into a renewable and environmentally friendly fuel. The goal of this source reduction project is to convert 5 million gallons of fats, oils and grease into 250K gallons of B100. The expected cost for the test program is $250K.

Enhance the Production of Biogas

Anaerobic digestion is almost as old as the planet itself. It is a process that, in the absence of oxygen, converts organic carbon into carbon dioxide (CO2) and methane (CH4)-a concoction called biogas, which can be used as an energy source. For more information, see the Region 9 Anaerobic Digestion Web site.

Wastewater treatment facilities can enhance the production of biogas with the anaerobic digestion of Fats, Oil, and Grease (FOG) and organic materials.

FOGs accumulate and can clog pipes and pumps both in the public sewer lines as well as in wastewater treatment facilities. Why clog pipes and pumps when you can become more energy efficient by digesting the fats, oil, and grease in an anaerobic digester?

Organic materials—including food waste, yard trimmings, soiled paper, and wood waste—compose two-thirds of the solid waste stream. The anaerobic digestion of food waste is growing in popularity as a means of recycling organic materials. In the absence of oxygen, the food waste is broken down—just like biosolids—and additional methane is produced. This is especially valuable in urban areas that do not have a lot of land for compost facilities.

Why would a wastewater treatment facility want to do this? There are several reasons:

- The wastewater treatment facility already has the technology to produce biogas.

- Biomass added to traditional wastewater feedstock increases the production of methane by approximately 30%.

- Landfills are the largest source of anthropogenic methane. Diverting food waste from landfills to wastewater treatment facilities allows for the capture of that methane, which can be used as on-site as a renewable source of energy.

- Wastewater treatment facilities can expect to see cost savings from incorporating FOGs and food waste into anaerobic digesters. This is because energy costs will be offset by the production of on-site power. In addition, facilities can charge waste haulers a tipping fee for accepting the FOGs and organics on-site.

- Most municipalities are investing in ways to divert materials from landfills. This is usually due to reduced landfill space and/or recycling goals. Wastewater treatment facilities offer the opportunity to divert large amounts of food waste, one of the largest waste streams still going to landfills.

Some examples of wastewater treatment facilities investigating FOGs and food waste include:

- Oakland, California

The East Bay Municipal Utility District (EBMUD) is probably best known for co-digesting their biosolids with food scraps. They add approximately 40 tons/day of food waste from Bay Area cities to their anaerobic digester, increasing methane production and energy yield. This POTW is taking their energy efficiency efforts a step further and wants to demonstrate the benefits and cost effectiveness of biodiesel as a clean, renewable alternative fuel for diesel engines. Grease waste trapped at restaurants will be used at EBMUD's Main Wastewater Treatment Plant in West Oakland. The fuel will power agency vehicles and demonstrate engine performance with waste grease derived biodiesel.

They add approximately 40 tons/day of food waste from Bay Area cities to their anaerobic digester, increasing methane production and energy yield. This POTW is taking their energy efficiency efforts a step further and wants to demonstrate the benefits and cost effectiveness of biodiesel as a clean, renewable alternative fuel for diesel engines. Grease waste trapped at restaurants will be used at EBMUD's Main Wastewater Treatment Plant in West Oakland. The fuel will power agency vehicles and demonstrate engine performance with waste grease derived biodiesel. - Millbrae, California

An example of a facility that is more energy efficient while also improving water quality. Grease causes sewage overflow spills when it clogs up sewer lines. Sewer overflows release raw sewage into the environment. By finding a way to use the grease to produce fuel that powers the wastewater treatment facility, they demonstrate that energy efficiency can also improve treatment performance.

- City of West Lafayette, IN

West Lafayette used CWSRF financing to establish a fats, oils and grease program, as well as a Cogeneration Facility at its wastewater treatment plant. The WWTP is receiving and treating fats, oils and grease to produce methane gas and an earth-like byproduct. The methane is used to generate electricity, providing environmental as well as economic benefits. The fats, oils, and grease program won PISCES award from the US EPA. (PDF) (5 pp, 2.46MB)

Additional Resources

- The Western Washington Cities Coalition has held webinars on "Biomethane as Transportation Fuel."

The two part webinar series includes Part I: Costs and Benefits for transportation, and Part II: Transportation Experience and Opportunities in Washington State.

The two part webinar series includes Part I: Costs and Benefits for transportation, and Part II: Transportation Experience and Opportunities in Washington State. - The Benefits of Anaerobic Digestion of Food Waste At Wastewater Treatment Facilities (PDF) (5 pp, 128K)

- The California Fats, Oils, and Grease work group (CAL FOG) lists grease haulers in California

as well as facilities accepting grease.

as well as facilities accepting grease.