Global Mitigation of Non-CO2 Greenhouse Gases: Magnesium Production

Key Points

- The global abatement potential of 98% is achieved through three abatement measures that substitute sulfur hexafluoride (SF6) with alternative gases.

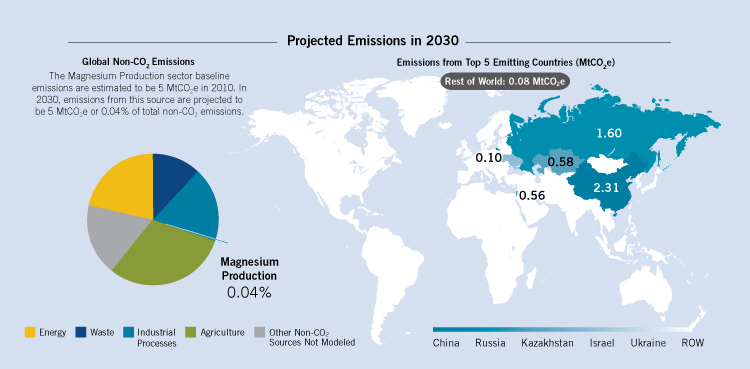

- From 2010 to 2030, SF6 emissions are projected to stay in the range of 5 million metric tons of carbon dioxide equivalent (MtCO2e).

- Full abatement potential can be achieved at break-even prices of $5/tCO2e or less.

Sector Description

Magnesium production uses SF6 as a cover gas during production and casting to prevent spontaneous combustion of molten magnesium in the presence of air. The use of SF6 can result in fugitive emissions during manufacturing processes. Advanced initiatives in the magnesium industry to phase out the use of SF6 have resulted in a 50% reduction in global SF6 emissions from 10 MtCO2e to 5 MtCO2e between 2000 and 2010.

View or download the full-size image here.(123 K, PNG)

View or download the full-size image here.(123 K, PNG)

Emissions Reduction Potential

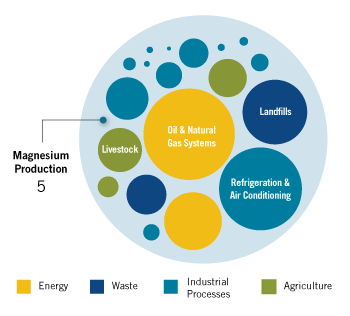

Assuming full implementation of current technology, emissions in the magnesium production sector could be reduced by up to 5 MtCO2e in 2030. This accounts for 0.11% of the 4,615 MtCO2e in global reduction potential in 2030.

View or download the full-size image here.(95 K, PNG)

View or download the full-size image here.(95 K, PNG)

Abatement Potential

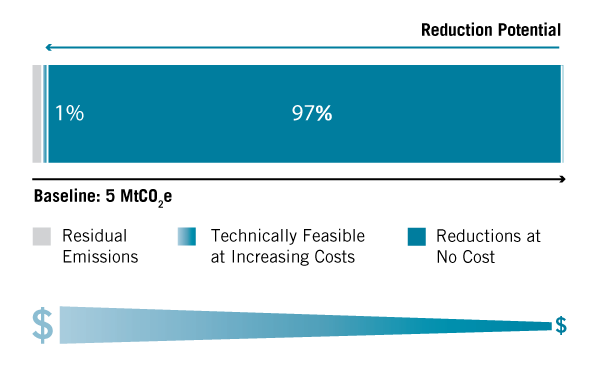

The global abatement potential of SF6 emissions in the magnesium sector is 5 MtCO2e, approximately 98% of projected emissions. The maximum reduction potential for the suite of reduction technologies is 98% of projected emissions in 2030. These reductions can be achieved at a cost of less than $5/tCO2e.

It would be cost-effective to reduce emissions by 97%, compared to the baseline, in 2030. An additional 1% reduction is available using technologies with increasingly higher costs.

It would be cost-effective to reduce emissions by 97%, compared to the baseline, in 2030. An additional 1% reduction is available using technologies with increasingly higher costs.

View or download the full-size image here.(35 K, PNG)

Abatement Measures

Three abatement measures are available for reducing SF6 emissions in production and processing, all of which involve replacing SF6 with an alternative cover gas: SO2, HFC-134a, or Novec 612. Although toxicity, odor, and corrosive properties are a concern of using SO2 as a cover gas, it can potentially eliminate SF6 emissions entirely through improved containment and pollution control systems. HFC-134a, along with other fluorinated gases, contains fewer associated health, odor, and corrosive impacts than SO2, but it does have global warming potential. Novec 612 is currently being used in a die-casting facility, and the replacement of SF6 with Novec 612 is under evaluation.

Emissions reductions by technology in 2030 at $0/tCO2e and at higher prices.

Emissions reductions by technology in 2030 at $0/tCO2e and at higher prices.

View or download the full-size image here.(40 K, PNG)