Global Mitigation of Non-CO2 Greenhouse Gases: Aluminum Production

Key Points

- Perfluorocarbon (PFC) emissions from aluminum production represent the third largest source of fluorinated greenhouse gas emissions in the industrial sector.

- Primary abatement measures include installation of or upgrades to process computer control systems and the installation of systems to allow more precise alumina feeding.

- Abatement measures in this sector have the potential to reduce over half of the projected baseline emissions.

Sector Description

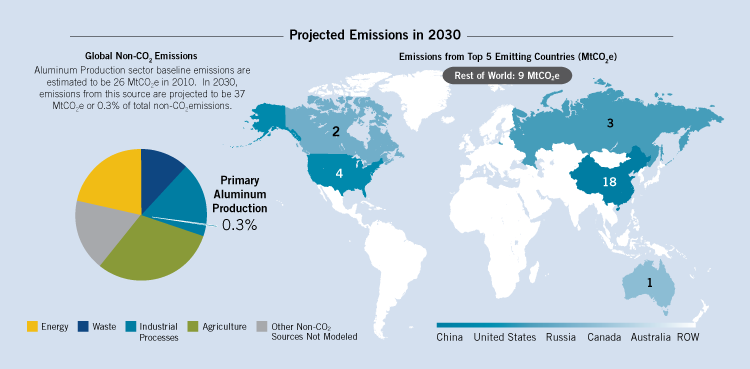

The aluminum production industry produces PFC emissions during brief process upset conditions in the aluminum smelting process. Despite a decline in global emissions of PFCs from primary aluminum production between 2000 and 2010, baseline emissions are projected to grow by 42%, from 26 million metric tons of carbon dioxide equivalent (MtCO2e) in 2010 to 37 MtCO2e in 2030.

View or download the full-size image here.(125 K, PNG)

View or download the full-size image here.(125 K, PNG)

Emissions Reduction Potential

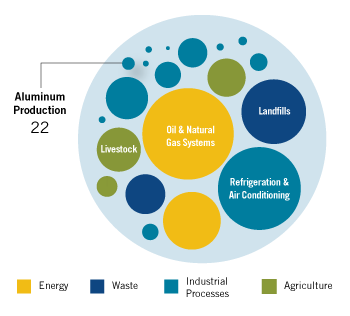

Assuming full implementation of current technology, emissions in the aluminum production sector could be reduced by up to 22 MtCO2e in 2030. This accounts for 0.47% of the 4,615 MtCO2e in global reduction potential in 2030.

View or download the full-size image here.(97 K, PNG)

View or download the full-size image here.(97 K, PNG)

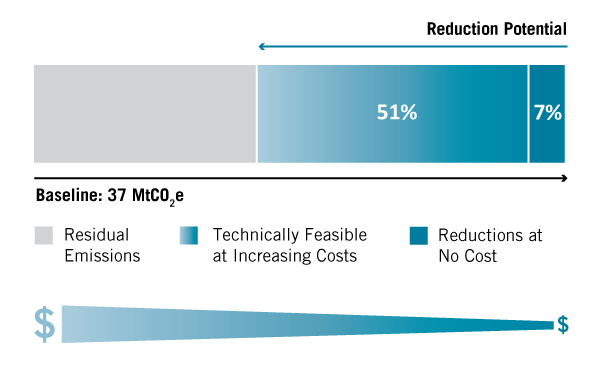

Abatement Potential

Global abatement potential in the primary aluminum sector is projected to be 21.6 MtCO2e, or nearly 58% of baseline emissions in 2030. In the absence of any policy incentive to reduce PFC emissions, cost-effective abatement of 2.5 MtCO2e is available. Additional mitigation is feasible with the adoption of more costly mitigation measures. In 2030, mitigation measures with costs less than or equal to $30/tCO2e have the potential to reduce emissions by 17 MtCO2e, or 80% of the total abatement potential.

It would be cost-effective to reduce emissions by 7%, compared to the baseline, in 2030. An additional 51% reduction is available using technologies with increasingly higher costs.

It would be cost-effective to reduce emissions by 7%, compared to the baseline, in 2030. An additional 51% reduction is available using technologies with increasingly higher costs.

View or download the full-size image here.(36 K, PNG)

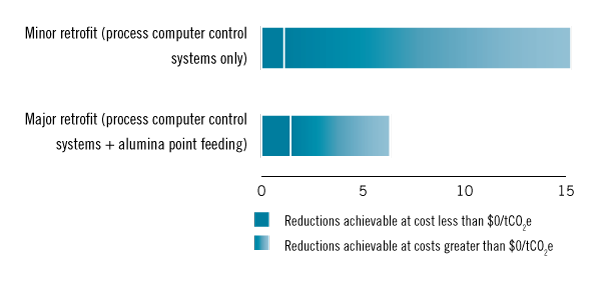

Abatement Measures

Abatement options in the primary aluminum production sector are primarily associated with installing or upgrading process computer control systems and alumina point-feed systems. The options considered involve 1) a minor retrofit to upgrade the process computer control systems and 2) a major retrofit to the process computer control systems coupled with the installation of alumina point-feed systems.

Emissions reductions by technology in 2030 at $0/tCO2e and at higher prices.

Emissions reductions by technology in 2030 at $0/tCO2e and at higher prices.

View or download the full-size image here.(33 K, PNG)