Global Mitigation of Non-CO2 Greenhouse Gases: Flat Panel Display Manufacturing

Key Points

- The global abatement potential of flat panel display (FPD) manufacturing processes is 10 million metric tons of carbon dioxide equivalent (MtCO2e) in 2030, 80% of baseline emissions.

- Six abatement options were analyzed to reduce emissions from etch and/or clean processes.

- No abatement potential is achievable at carbon prices below $25/tCO2e.

Sector Description

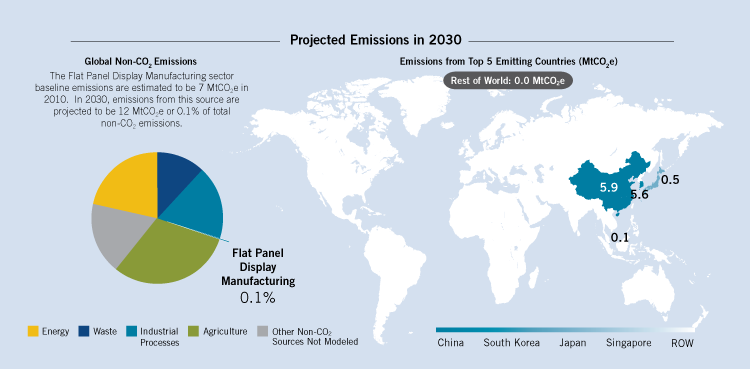

FPD manufacturing processes produce fluorinated greenhouse gas (F-GHG) emissions, including sulfur hexafluoride (SF6), nitrogen trifluoride (NF3), and carbon tetrafluoride (CF4). Global baseline emissions from the FPD manufacturing sector in 2010 were estimated at 7 MtCO2e. Baseline emissions for 2020 are projected to increase to approximately 12 MtCO2e and remain at 12 MtCO2e through 2030.

View or download the full-size image here.(120 K, PNG)

View or download the full-size image here.(120 K, PNG)

Emissions Reduction Potential

Assuming full implementation of current technology, emissions in the FPD manufacturing sector could be reduced by up to 10 MtCO2e in 2030. This accounts for 0.21% of the 4,615 MtCO2e in global reduction potential in 2030.

View or download the full-size image here.(99 K, PNG)

View or download the full-size image here.(99 K, PNG)

Abatement Potential

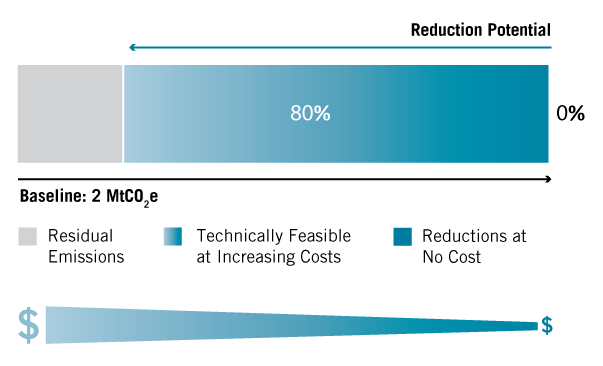

Global abatement of F-GHGs in the FPD manufacturing sector is estimated to be 9 MtCO2e in 2020 and 10 MtCO2e in 2030, which equates to 80% abatement from projected baseline emissions. At a break-even price of $30, just over 2 MtCO2e in emissions reductions are achievable in 2030. No emissions reductions are possible at prices below $25.

It would be cost-effective to reduce emissions by 0%, compared to the baseline, in 2030. An additional 80% reduction is available using technologies with increasingly higher costs.

It would be cost-effective to reduce emissions by 0%, compared to the baseline, in 2030. An additional 80% reduction is available using technologies with increasingly higher costs.

View or download the full-size image here.(38 K, PNG)

Abatement Measures

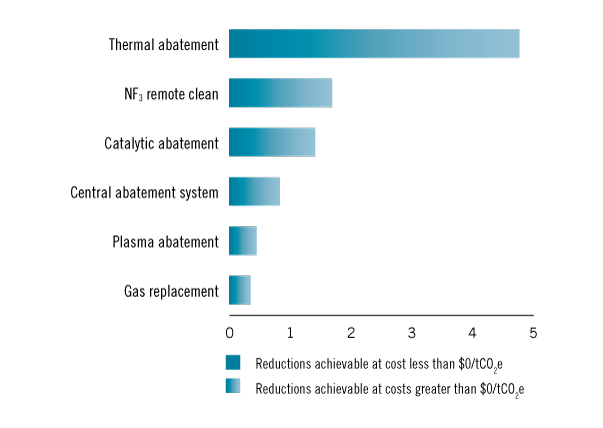

Six abatement options were considered for the FPD manufacturing sector: central abatement, thermal abatement, catalytic abatement, plasma abatement, NF3 remote chamber clean, and gas replacement. These systems are applicable to reducing emissions from etch and/or clean processes. Thermal abatement systems represent the largest abatement potential, accounting for 40% of emissions reductions in the FPD manufacturing sector.

Emissions reductions by technology in 2030 at $0/tCO2e and at higher prices.

Emissions reductions by technology in 2030 at $0/tCO2e and at higher prices.

View or download the full-size image here.(41 K, PNG)