TENORM: Coal Combustion Residuals

Burning coal in boilers to create steam for power generation and industrial applications produces a number of coal combustion residuals. Naturally radioactive materials that were in the coal mostly end up in fly ash, bottom ash and boiler slag![]() slagByproduct left after a desired metal is thermally separated from its raw ore.. These residuals are called Technologically Enhanced Naturally Occurring Radioactive Materials (TENORM) because burning removes the coal's organic constituents, concentrating the trace amounts of naturally occurring radionuclides:

slagByproduct left after a desired metal is thermally separated from its raw ore.. These residuals are called Technologically Enhanced Naturally Occurring Radioactive Materials (TENORM) because burning removes the coal's organic constituents, concentrating the trace amounts of naturally occurring radionuclides:

- Uranium.

- Thorium.

- Potassium.

- Their radioactive decay products

decay productsThe atoms formed and the energy and particles emitted as radioactive material decays to reach a stable form., including radium.

decay productsThe atoms formed and the energy and particles emitted as radioactive material decays to reach a stable form., including radium.

About 80 to 90 percent of fly ash, bottom ash and boiler slag consists of non-radioactive minerals, typically silicon, aluminum, iron and calcium.

Learn more about TENORM-producing industries and sources in the United States.

Waste Generation

In 2012, 59 percent of the coal consumed by electric utilities and independent power producers in the United States resulted in the generation of about 68 million tons of fly ash, bottom ash and boiler slag. Learn more about coal ash. An additional 42 million tons of other residuals were generated from flue gas desulfurization and fluidized bed combustion, according to the American Coal Ash Association (ACAA) Survey Report (PDF) (1 p, 94 K About PDF). Exit

-

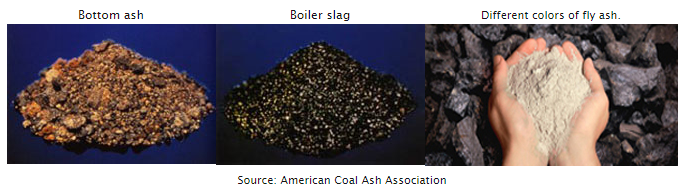

Fly ash is carried up with hot flue gases and trapped by stack filters. It is the largest of the coal combustion residuals (about half) by weight.

-

Bottom ash is too large or heavy to be carried by flue gases and settles to the bottom of the boiler. Just over ten percent of coal combustion residuals is bottom ash.

- Boiler slag is formed when the ash melts under the intense heat of combustion and collects at the bottom of the boiler and in exhaust stack filters. It makes up about two percent of coal combustion residuals.

Stack filtration devices, such as electrostatic precipitators, baghouses and scrubbers are routinely used to reduce the emission of fly ash. They are about 99 percent effective. Only about one percent is released into the air.

The amount of ash produced depends on the mineral content of the coal and the type of boiler. The typical natural content of minerals in coal used in the U.S. ranges from about three percent to 30 percent. The average is about 10 percent, depending upon the region from which the coal was mined. Some utilities are selecting coal with lower mineral (or ash) content to meet particulate emission standards. In other instances, utilities reduce the ash content by washing the coal. Washing can reduce the ash content by as much as 50 to 70 percent.

Disposal and Reuse

The ACAA survey showed that about 45 percent of all fly ash, bottom ash and boiler slag was reused. Its use depended on characteristics of the ash:

- Fly Ash: Just over 60 percent of its reported use was in concrete and blended cement. It can typically be substituted for cement at a rate of 10-40 percent. Fly ash makes up about one to four percent of concrete.* The remaining usage was as structural fills/embankments, in road base, for snow and ice control and waste stabilization/solidification. EPA has limitations on the use of unencapsulated fly ash. Learn more on the Coal Ash Reuse webpage.

- Bottom Ash: Almost 70 percent of its use was for concrete, blended cement and structural fills/embankments. The remaining usage was as road base, in snow and ice control, for mining applications and as an aggregate.

- Boiler Slag: Eighty percent of its use was as blasting grit/roofing granules. The remaining usage was as structural fills/embankments, in road base, for snow and ice control and as aggregate.

The fly ash, bottom ash and boiler slag that was not reused, about 55 percent of the total generated, was disposed in landfills and surface impoundments. There are regulations for the construction and maintenance of those impoundments. Learn about the Final Rule: Disposal of Coal Combustion Residuals from Electric Utilities.

* Portland cement makes up about 10 percent of concrete. Typically 10 to 40 percent of the cement is replaced with fly ash, making the final mix of fly ash in concrete range from one to four percent.