Pollution Prevention (P2) and TRI

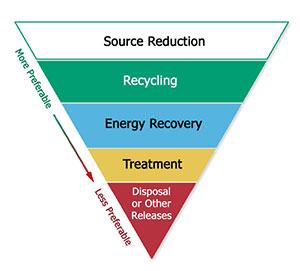

Under the Pollution Prevention Act of 1990 (PPA), TRI collects information to track industry progress in reducing waste generation and moving towards safer waste management alternatives. Many facilities provide descriptions on measures they have taken to prevent pollution and reduce the amount of toxic chemicals entering the environment. As a result, TRI serves as a tool for identifying effective environmental practices and highlighting pollution prevention successes.

Access TRI's P2 Data

- Use the P2 Search Tool to get info by industry sector, chemical, geography or parent company, and compare performance

- Use the TRI Search Tool to find facility specific P2 data

- See how P2 is featured in the TRI National Analysis

- Download all P2 data for 2015, 2014, 2013, 2012, or 2011 (Excel)

- Read about the TRI Food Sector in the National Analysis and explore the data using the new visualization Food App.

- Browse P2 Spotlights and possible alternative solutions for TRI chemicals

Learn About TRI P2 Resources

- Browse TRI's collection of P2 resources, including factsheets, videos, tips for reporting P2 activities to TRI, how-to guidance for conducting analyses with the TRI P2 Search Tool, and links to P2-related publications.

- Learn about other EPA P2 resources such as EPA’s P2 and Sustainability Programs and Agency efforts to achieve Sustainable Food Management.

Source Reduction Activities Reported to TRI

For 2015, a total of 2,424 facilities (11% of all TRI facilities) reported initiating 7,508 source reduction activities. Good operating practices, process modifications, and spill and leak prevention were the activities reported most frequently.

View Examples

Click on the legend or graph to see examples of source reduction activities.

Good Operating Practices (3,002)

Good Operating Practices (3,002)

Examples:

- A pesticide manufacturer validated their rinse procedures to minimize the number of dichloromethane rinse cycles required.

- A soap manufacturer changed production schedules to allow for longer run times for similar products to reduce the need for diethanolamine feedstock changeovers.

Process Modifications (1,578)

Process Modifications (1,578)

Examples:

- A battery manufacturer upgraded its conveyor system to prevent blockage and loss of cobalt material due to contamination.

- Through an employee recommendation, a paper manufacturer reduced the volume of methyl isobutyl ketone used by switching to a different process catalyst.

Spill and Leak Prevention (941)

Spill and Leak Prevention (941)

Examples:

- A petroleum terminal installed spill kits and drain covers in high-risk areas to prevent benzene spills from leaving through storm water drains.

- A chemical manufacturing facility worked with a leak detection and repair contractor to monitor their anhydrous ammonia system to reduce fugitive emissions.

Raw Material Modifications (656)

Raw Material Modifications (656)

Examples:

- A motor vehicle parts manufacturer eliminated use of N-methyl-2-pyrrolidone (NMP) as a reducing solvent and when possible started using paints that do not contain NMP.

- A rubber product manufacturer has been replacing di (2-ethylhexyl) phthalate with more environmentally friendly alternatives for its rubber formulations.

Inventory Control (686)

Inventory Control (686)

Examples:

- A storage battery manufacturer worked with a vendor to understand shelf-life risks and perform in-house lab testing to identify issues involved with using recently outdated cobalt material.

- For better control over the volume of nitric acid added to chromate solution, a fabricated metal facility changed container size from 15 gallons to 1 gallon bottles.

Product Modifications (300)

Product Modifications (300)

Examples:

- A wood product manufacturer reduced formaldehyde use by changing resin mixtures for several products.

- A motor and generator manufacturer modified composition of many of their products by substituting lead-free solders where feasible.

Cleaning and Degreasing (182)

Cleaning and Degreasing (182)

Examples:

- A glass manufacturer installed a deionized water cleaning system which produces cleaner product for the calibration operation that uses mercury. As a result, less maintenance is required, resulting in decreased mercury waste.

- With the help of a vendor, a food manufacturing facility substituted a high nitric acid sanitation chemical to an equally effective low nitric acid chemical.

Surface Preparation and Finishing (163)

Surface Preparation and Finishing (163)

Examples:

- A plastic parts manufacturer worked with their paint supplier to select a water-based coatings that would perform as well as a solvent-based coating, resulting in a large reduction of xylene usage.

- A household cooking appliance manufacturer upgraded their spray guns to provide better coverage and use less nickel material.