Questions and Answers About Alternatives in Each Sector

The following list of questions and answers provides an overview of the regulations governing the use of substitutes that are reviewed under the Significant New Alternatives Policy (SNAP) program in various industrial sectors including the following:

- Adhesives, Coatings, and Inks

- Aerosols

- Fire Suppression and Explosion Protection

- Foam Blowing Agents

- Refrigeration and Air Conditioning

- Cleaning Solvents

Adhesives, Coatings, and Inks

Lists of Adhesives, Coatings, and Inks Substitutes

1. How does the SNAP program regulate carrier solvents used in adhesives, coatings, and inks?

EPA’s SNAP program in this sector is aimed at reviewing substitutes used in the formulations of adhesives, coatings, or inks. Under the SNAP program, coatings are “durable and decorative coatings” such as paints or wood stains. Below is a table outlining which end-uses are subject and not subject to SNAP review. A majority of those applications that are subject to review formerly used methyl chloroform (1,1,1-trichloroethane or TCA) widely.

Lubricant and medical coatings, however, are not currently regulated under SNAP. It is possible that the Agency may expand the scope of SNAP to cover an application that it has not historically regulated under the program, if EPA determines that the use of substitutes in that application poses a significant environmental or health risk.

| Applications Subject to SNAP Review | Applications Not Subject to SNAP Review | |

|---|---|---|

|

Adhesives |

|

|

|

Coatings |

|

|

|

Inks |

|

Aerosols

1. What is covered in the aerosol sector?

The aerosol sector includes aerosol solvents and aerosol propellants. An aerosol is a liquid or solid that is suspended in the air in tiny particles or droplets once it is released from its container. The SNAP program reviews individual solvents, rather than aerosol solvent blends. If an aerosol blend contains only solvents that are acceptable under SNAP, you may use the blend. A blend of two or more of these acceptable aerosol solvents, and no others, does not need to be submitted separately for review as an aerosol solvent. Alternative technologies that function similarly to aerosol propellants are also acceptable substitutes, such as pumps, mechanical pressure dispensers, or non-spray dispensers.

2. Can I use hydrochlorofluorocarbons (HCFCs) for aerosols?

No. Aerosol uses are subject to the requirements under section 605 of the CAA. As of January 1, 2015, Section 605(a) of the CAA prohibits the introduction into interstate commerce or use of hydrofluorochlorocarbons (HCFCs) unless the substance:

- Has been used, recovered, and recycled;

- Is used and entirely consumed (except for trace quantities) in the production of other chemicals;

- Is used as a refrigerant in appliances manufactured before January 1, 2020; or

- Is listed as acceptable for use as a fire suppression agent for nonresidential applications.

Imported aerosols are subject to the SNAP requirements under sections 610 and 612 of the CAA. Section 610 prohibits the sale, distribution, and offer for sale or distribution of nonessential products containing ozone-depleting chlorofluorocarbons (CFCs) or HCFCs. Nonessential products include any aerosol product or pressurized dispenser unless the use of the aerosol product or pressurized dispenser is determined by EPA to be essential as a result of flammability or worker safety concerns.

Fire Suppression and Explosion Protection

A. The Phaseout of Halons

1. When was the production of halons banned?

Under the Clean Air Act (CAA), the United States banned the production and import of virgin halons 1211, 1301, and 2402 in January 1, 1994 in compliance with the Montreal Protocol. In 2010, global production of halon for fire protection was phased out under the Montreal Protocol. Continuing uses of halons to service existing systems, for military legacy systems, and for certain aviation applications must rely on supplies of recycled halons where these may be available.

2. Are there any federal laws on emissions of halons?

EPA established requirements under CAA Section 608 (63 FR 11084; March 5, 1998) that prohibits the intentional release of halon 1211, halon 1301, and halon 2402 during the testing, repairing, maintaining, servicing, or disposal of halon-containing equipment or during the use of such equipment for technician training. The rule also requires appropriate training of technicians regarding emissions reduction and proper disposal of halon and halon-containing equipment. See the halon guidance document for more information.

3. Are there any restrictions on the use of halocarbon or inert gas agents for fire suppression?

The key factor in assessing the safety of a halocarbon flooding agent is cardiac sensitization, the increased sensitivity of the heart to adrenaline induced by exposure to high concentrations of certain chemicals. The amount of flooding agent required to extinguish a fire is compared to results of a standard protocol to determine an agent's cardiosensitization levels. This is known as comparing the design concentration to the No Observed Adverse Effect Level (NOAEL) and the Lowest Observed Adverse Effect Level (LOAEL) for cardiac sensitization. For inert gas agents, the human health effect of concern is reduction of oxygen in the protected enclosure to potentially unsafe levels. Inert gas systems lower the oxygen in a room to a level that will not sustain combustion, while remaining high enough to sustain human life.

- In a final rule (67 FR 4185; January 29, 2002), EPA rescinded the use conditions imposed under the SNAP program that limited human exposure to halocarbon and inert gas agents used in the fire suppression and explosion protection industry. These use conditions were redundant with safety standards that had been established by the National Fire Protection Association (NFPA) Exit since the original 1994 SNAP rulemaking and listings for these agents. NFPA’s 2001 Standard for Clean Agent Fire Extinguishing Systems, Exit a voluntary consensus standard to address design, installation, maintenance and operation of systems using these alternatives, is the basis for regulation of halon replacement systems throughout North America and is also widely used in other parts of the world.

4. Are hydrochlorofluorocarbons (HCFCs) acceptable as halon substitutes?

EPA allows the sale and distribution of certain HCFCs and HCFC blends listed as acceptable under SNAP for use in portable fire extinguishers in non-residential applications.

5. What are the SNAP limitations on using a perfluorocarbon (PFC) (e.g., C4F10, C6F14, C3F8) in the United States?

EPA established narrowed use limits imposed on the use of certain HFCs and PFCs to restrict the use of these agents because of their high global warming potentials. PFCs and HFC-23 also have relatively long atmospheric lifetimes. PFCs may only be used where no other agent is technically feasible due to performance or safety requirements. The user must conduct an evaluation of the other alternatives and must determine that they either will not perform properly or that they will pose a risk to human health.

6. Do I have to obtain EPA approval to use a PFC?

No approval is required from EPA. However, the user must maintain documentation of the evaluation.

7. What is the SNAP status of alternative technologies such as water mist and powdered aerosols?

Non-halocarbon systems are considered "alternative technologies" and are subject to EPA SNAP review. A number of alternative technologies have been listed acceptable under SNAP, and some are subject to use conditions or restrictions. See the SNAP Fire Suppression and Explosion Protection page for more details.

8. Are there conditions on using water mist or water fog systems?

EPA has listed water mist systems using potable water or natural seawater as acceptable without use restrictions or conditions. However, any system with an additive must be reviewed by EPA on a case-by-case basis.

9. Can I use a powdered aerosol in a total flooding system in an occupied area?

Powdered aerosols in total flooding systems must undergo a review for physiological effects to be listed as acceptable in normally occupied areas.

10. Who are the manufacturers of some of the fire suppression substitutes?

Halon Alternatives Research Corporation (HARC), Exit a non-profit trade association formed in 1989 to promote the development and approval of environmentally acceptable halon alternatives, maintains a list of equipment manufacturers.

11. What are other government regulations or industry standards concerning fire suppressants?

The National Fire Protection Association (NFPA) Exit has published standards for agents used in total flooding systems including “NFPA 2001 - Standard on Clean Agent Extinguishing Systems,” Exit “NFPA 2010 – Standard for Fixed Aerosol Fire-Extinguishing Systems,” Exit and “NFPA 750 - Standard for the Installation of Water Mist Fire Protecting System.” Exit In addition, manufacturers of systems containing the new alternative agents often obtain Underwriters Laboratories (UL) or Factory Mutual (FM) certification, therefore certain standards may apply to the products.

B. Halon Recycling and Banking

1. What is the Halon Recycling Corporation?

The Halon Recycling Corporation (HRC) Exit is a voluntary, non-profit trade association formed by concerned halon users and the fire protection industry to support the goals of the environmental community and EPA. HRC was established as an information clearinghouse on all issues relating to halon recycling. It facilitates halon recycling and determines critical halon use. Specifically, HRC assists sellers with the disposal of halon in a responsible manner, and helps buyers locate supplies of Halon 1301 and Halon 1211 for recharging their existing systems.

2. Where can I purchase recycled halon?

Recycled halon can be purchased from many halon and fire protection equipment distributors or directly from owners who are decommissioning their halon systems. In addition, the HRC may be able to provide information on such sellers.

3. Are there standards for recycled halon?

The military specification for halon 1211 has been revised to allow the use of recycled halon. ASTM has developed D5632-95 (Standard Specification for halon 1301) and D5631-94 (Standard Practice for Handling Transportation and Storage of halon 1301). ISO 7201 contains standards for halon 1211 and halon 1301.

4. Is halon recycling equipment available?

Yes. Several manufacturers have developed recycling equipment for both halon 1301 and halon 1211 that recovers 98 to 99 percent of the halon and some units can reclaim it to meet certain specifications. Contact the HRC for the list of vendors of recycling equipment.

5. Can I import halon?

It is legal under the Montreal Protocol and the U.S. CAA to import recycled halon, i.e., halon that has been recovered from a fire suppression system. Each individual shipment of recycled halon requires prior EPA approval. Approved imports that enter the United States must be reported to EPA on a quarterly basis. Newly produced halon or halon never installed in a fire suppression system may not be imported into the country. The Internal Revenue Service (IRS) imposes a tax on certain ozone-depleting chemicals. More details on taxes for ozone-depleting chemicals can be found on the IRS’s website.

A Final Rule exempting aircraft halon 1301 system bottles from the ODS import petition requirement was published on March 10, 2009 (74 FR 10182). This Final Rule exempts imports of spherical pressure vessels containing halon 1301 for aircraft fire extinguishing (“aircraft halon bottles”') for purposes of hydrostatic testing from EPA’s ODS petition process while recordkeeping and reporting requirements remain.

C. Halon Disposal

1. I am removing halon from my systems and I do not want to use it again. What can I do with it?

You can:

- Make it available to the HRC;

- Donate it to the Department of Defense Ozone-Depleting Substances Reserve (DoD bank);

- Return it to your distributor for resale; or

- Send it to a halon recycler.

The federal law on the disposal of halons or halon-containing equipment is discussed in question 4 below.

2. Will the HRC collect my halon?

No. The HRC is not a physical "bank," but is an information clearinghouse that will help you locate a user with a critical need for your halon. The HRC is discussed in Part B (Halon Recycling and Banking).

3. What is the DoD bank?

The Defense Logistics Agency (DLA) manages the DoD ODS Reserve for the U.S. military in order to maintain a reserve of halons 1202, 1211, and 1301 to support "mission critical" requirements when commercial sources are not available. DLA has a policy to rely primarily on DoD turn-ins of recovered halons for future use.

4. Are there any federal laws on the disposal of halons and halon-containing equipment?

Since 1998, EPA's final rule (63 FR 11084; March 5, 1998) established that halon-containing equipment must be properly disposed of at the end of its useful life. That is, such equipment must be sent for halon recovery and the halon itself must be sent to a halon recycling facility operating. More details can be found on EPA's Halon Handling page.

D. Section 611 Labeling

1. What has to be labeled?

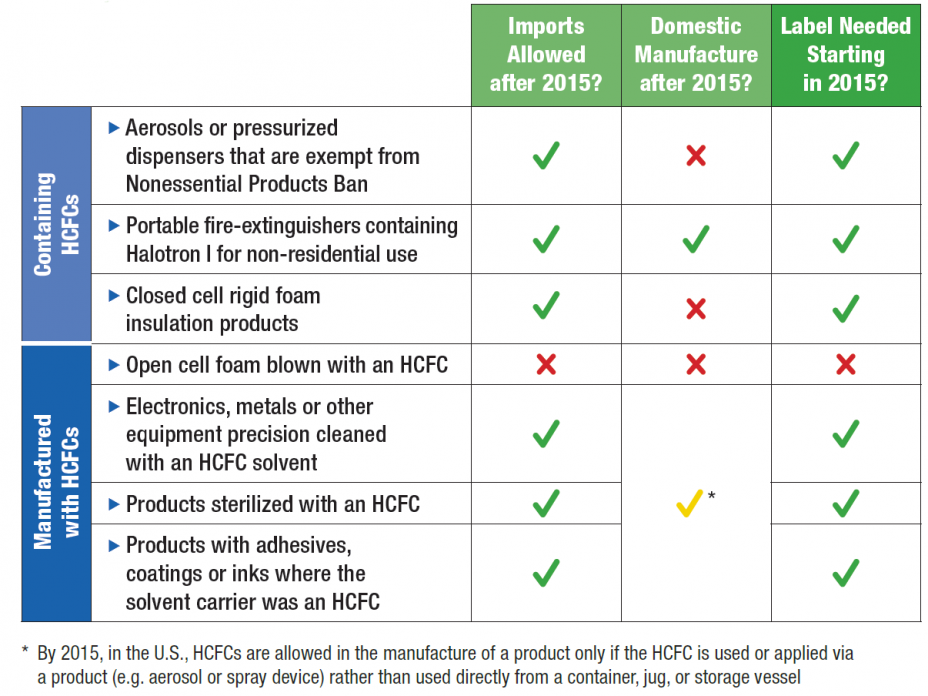

Products imported or manufactured after January 1, 2015 that contain or were manufactured with a hydrochlorofluorocarbon (HCFC) must bear a warning label before they can be introduced into interstate commerce. Imported products must be labeled before clearing U.S. Customs.

A summary of the products impacted by Section 611 labeling requirements is provided below:

2. What must the label say and where should it appear?

The purpose of the label is to allow consumers to make informed choices before buying products containing or manufactured with HCFCs. To that end, the warning statement must be clearly legible and conspicuous such that it is likely to be read by consumers prior to making their purchase. The label must include the following statement:

WARNING: [Contains/ Manufactured with] [name of HCFC], a substance that harms public health and environment by destroying ozone in the upper atmosphere.

The warning may be printed directly on a product or its outer packaging or on an alternative label, including the following conspicuous placements:

- Principal display panel or display panel area

- Alternative labels, such as hang tags, stickers, or similar over-labeling

- Outer packaging

- Supplemental printed materials, such as invoices, bills of lading, or package inserts

- Promotional materials, such that the warning statement is visible before the time of purchase

Foam Blowing Agents

1. Can I use hydrochlorofluorocarbons (HCFCs) as foam blowing agents?

No. Foam blowing agents are subject to the requirements under section 605 of the CAA. As of January 1, 2015, Section 605(a) of the CAA prohibits the introduction into interstate commerce or use of HCFCs unless the substance:

- Has been used, recovered, and recycled;

- Is used and entirely consumed (except for trace quantities) in the production of other chemicals;

- Is used as a refrigerant in appliances manufactured before January 1, 2020; or

- Is listed as acceptable for use as a fire suppression agent for nonresidential applications.

2. I switched to a hydrofluorocarbon (HFC) blowing agent. How long will I be able to use it?

Under the SNAP program’s Change of Listing Status Final Rule published on July 20, 2015, various HFC and HFC-containing blends that were previously listed as acceptable alternatives will be listed as unacceptable (or acceptable with restrictions for certain uses) in various foam-blowing end-uses where other alternatives are available (or potentially available) that pose lower overall risk to human health and the environment. Please refer to the final rule for more details of the status changes of specific HFCs in specific end-uses.

Furthermore, because the SNAP program evolves the list of substitutes as EPA makes decisions informed by its overall understanding of the environmental and human health impacts as well as its current knowledge about available substitutes, please refer to the website for the most up-to-date list of acceptable alternatives in all foam blowing agent end-uses.

3. Are all foam types covered under SNAP?

SNAP includes the following end-uses:

- Rigid polyurethane and polyisocyanurate laminated boardstock;

- Rigid polyurethane appliance;

- Rigid polyurethane spray, commercial refrigeration, and sandwich panels;

- Rigid polyurethane slabstock and other foams;

- Polystyrene extruded insulation boardstock and billet;

- Phenolic insulation board and bunstock;

- Flexible polyurethane;

- Polystyrene extruded sheet; and

- Polyolefin.

4. Is the review of use of an additive in a substitute foam blowing agent that is already found acceptable under SNAP required?

Under the SNAP program, changes in foam formulation (aside from the blowing agent) are not formally subject to review. Nonetheless, the manufacturer overseeing the formulation change is required to notify the Agency if these modifications influence the human health or environmental risk characteristics associated with the substitute.

5. Is a submission required for foam blowing agent blends?

A submission is required for blends of blowing agents for certain end-uses, including blends with blowing agents that are already listed as acceptable. The table below summaries the end-uses in which a submission is required and those in which it is permissible to blend blowing agents that are already listed as acceptable, without an additional submission for the blend.

| Submission Required for Blends | Blending Permissible if Blowing Agents are Listed as Acceptable |

|---|---|

|

|

a For spray foam, if any components of the blend are flammable, then a submission is required specifically for the blend.

b For spray foam, if all components of the blend are acceptable and non-flammable, then it is permissible to blend those blowing agents without submission specifically for the blend.

6. What foam products have to be labeled?

See Part D under Fire Suppression and Explosion Protection for further information regarding Section 611 labeling requirements.

Refrigeration and Air Conditioning

1. What is Freon?

"Freon" is a trade name for chlorofluorocarbon (CFC![]() CFCA compound consisting of chlorine, fluorine, and carbon. CFCs are very stable in the troposphere. They move to the stratosphere and are broken down by strong ultraviolet (UV) light, where they release chlorine atoms that then deplete the ozone layer. CFCs are commonly used as refrigerants, solvents, and foam blowing agents. The most common CFCs are CFC-11, CFC-12, CFC-113, CFC-114, and CFC-115. The ozone depletion potential (ODP) for each CFC is, respectively, 1, 1, 0.8, 1, and 0.6. A table of all ozone-depleting substances (/ods-phaseout) shows their ODPs, global warming potentials (GWPs), and CAS numbers. CFCs are numbered according to a standard scheme (http://www3.epa.gov/ozone/geninfo/numbers.html).) and hydrochlorofluorocarbon (HCFC

CFCA compound consisting of chlorine, fluorine, and carbon. CFCs are very stable in the troposphere. They move to the stratosphere and are broken down by strong ultraviolet (UV) light, where they release chlorine atoms that then deplete the ozone layer. CFCs are commonly used as refrigerants, solvents, and foam blowing agents. The most common CFCs are CFC-11, CFC-12, CFC-113, CFC-114, and CFC-115. The ozone depletion potential (ODP) for each CFC is, respectively, 1, 1, 0.8, 1, and 0.6. A table of all ozone-depleting substances (/ods-phaseout) shows their ODPs, global warming potentials (GWPs), and CAS numbers. CFCs are numbered according to a standard scheme (http://www3.epa.gov/ozone/geninfo/numbers.html).) and hydrochlorofluorocarbon (HCFC![]() HCFCA compound consisting of hydrogen, chlorine, fluorine, and carbon. The HCFCs are one class of chemicals being used to replace the CFCs. They contain chlorine and thus deplete stratospheric ozone, but to a much lesser extent than CFCs. HCFCs have ozone depletion potentials (ODPs) ranging from 0.01 to 0.1. Production of HCFCs with the highest ODPs are being phased out first, followed by other HCFCs. A table of ozone-depleting substances (http://www.epa.gov/ods-phaseout/phaseout-class-ii-ozone-depleting-substances) shows their ODPs, GWPs, and CAS numbers. HCFCs are numbered according to a standard scheme (http://www3.epa.gov/ozone/geninfo/numbers.html).) refrigerants sold by Chemours, formally DuPont. Other trade names include Honeywell's "Genetron" and Arkema's "Forane." Various companies have sold the same CFCs, HCFCs, hydrofluorocarbons (HFCs

HCFCA compound consisting of hydrogen, chlorine, fluorine, and carbon. The HCFCs are one class of chemicals being used to replace the CFCs. They contain chlorine and thus deplete stratospheric ozone, but to a much lesser extent than CFCs. HCFCs have ozone depletion potentials (ODPs) ranging from 0.01 to 0.1. Production of HCFCs with the highest ODPs are being phased out first, followed by other HCFCs. A table of ozone-depleting substances (http://www.epa.gov/ods-phaseout/phaseout-class-ii-ozone-depleting-substances) shows their ODPs, GWPs, and CAS numbers. HCFCs are numbered according to a standard scheme (http://www3.epa.gov/ozone/geninfo/numbers.html).) refrigerants sold by Chemours, formally DuPont. Other trade names include Honeywell's "Genetron" and Arkema's "Forane." Various companies have sold the same CFCs, HCFCs, hydrofluorocarbons (HFCs![]() HFCsCompounds containing only hydrogen, fluorine, and carbon atoms. They were introduced as alternatives to ozone depleting substances in serving many industrial, commercial, and personal needs. HFCs are emitted as by-products of industrial processes and are also used in manufacturing. They do not significantly deplete the stratospheric ozone layer, but they are powerful greenhouse gases with global warming potentials ranging from 140 (HFC-152a) to 11,700 (HFC-23).), and other products under different names. Some users will use “freon” to describe refrigerants in general, even those (such as HFCs) that do not use that word as a trade name.

HFCsCompounds containing only hydrogen, fluorine, and carbon atoms. They were introduced as alternatives to ozone depleting substances in serving many industrial, commercial, and personal needs. HFCs are emitted as by-products of industrial processes and are also used in manufacturing. They do not significantly deplete the stratospheric ozone layer, but they are powerful greenhouse gases with global warming potentials ranging from 140 (HFC-152a) to 11,700 (HFC-23).), and other products under different names. Some users will use “freon” to describe refrigerants in general, even those (such as HFCs) that do not use that word as a trade name.

2. What alternative refrigerants are currently available? How do I know what I'm allowed to use?

Several new alternatives are on the market. The SNAP website contains the latest list of acceptable substitutes by end-use. Another table lists the compositions of many blends, their designations under international standards (e.g., ASHRAE 34 and ISO 817), and the generic names, if any, used when describing them in the Federal Register.

3. Who do I contact for information about substitutes?

Substitute refrigerants are made by many chemical manufacturers and are sold through a wide distribution chain. A list of chemical manufacturers and the refrigerants that they manufacture can be found on the Refrigeration and Air Conditioning page.

4. What are use conditions? Do I have to meet them?

In some cases, EPA believes that substitutes pose an undue risk to human health and the environment unless the user meets specific conditions on how the substitute is used. Such substitutes are listed as acceptable subject to use conditions. For example, EPA may require that warning labels be included for certain refrigerants or that the amount used in any particular product be limited. Users must meet such conditions, or they will be in violation of the SNAP rule.

5. Will EPA recommend the best substitute for my equipment?

No, EPA only determines what substitutes are acceptable from an environmental and human health perspective. EPA does not test refrigerants for their effectiveness as part of the SNAP process. EPA firmly believes that the market should determine which of the acceptable alternatives will work the best and gain the largest market share.

6. I don't see any substitutes listed for my equipment. How do I find out what is available?

The SNAP program has identified eight major industrial use sectors, and several end-uses within each sector.

7. Are there any safety considerations for new refrigerants?

EPA believes that adherence to Standard 15 of the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) will ensure the safety of technicians and building occupants. This standard applies to the use of alternative refrigerants. In addition, systems designed and operated in accordance with ASHRAE Standard 15 will leak minimal amounts of refrigerant, thereby reducing ozone depletion and global warming impacts.

8. Are flammable refrigerants automatically unacceptable?

EPA considers flammability as one factor of many within the SNAP risk screening process. For all end-uses except MVAC, rather than serving to disqualify a substitute, flammability may necessitate additional testing and assessment of risk. The risks from using a flammable refrigerant, such as a hydrocarbon, are dependent on the conditions and type of equipment. EPA has listed flammable refrigerants as acceptable and, where appropriate, EPA includes use conditions to ensure safety. See the Refrigeration and Air Conditioning section of the site for information on acceptable flammable refrigerants and use conditions.

9. What are my choices for motor vehicle air conditioning?

For additional information on MVAC alternatives, see EPA’s website on “Vehicle Air Conditioning Refrigerant Transition & Environmental Impacts.”

10. What other alternative technologies are available?

Several other technologies are available as an alternative to vapor compression and absorption cycle equipment. Processes such as desiccant cooling, evaporative cooling, and other innovative solutions exist for various end-uses. For example, evaporative cooling, which uses the evaporation of water to effect cooling, is currently available in systems designed to cool homes, office buildings, and transit buses.

11. How are refrigerants listed as acceptable under SNAP described the SNAP Notices and Rules?

Wherever possible, EPA will use designations for refrigerants from international standards such as ASHRAE 34 and ISO 817. In cases when refrigerant compositions are confidential, EPA will use trade names. In some cases, SNAP has used generic names (e.g. “HCFC Blend Beta”) instead of trade names in the Federal Register; a list is available that connects generic names to trade names. A list of refrigerant blends and respective compositions are included here.

Solvents

1. What is the definition of “non-aerosol solvent cleaning”?

In this sector, EPA has historically applied SNAP only to large industrial cleaning applications, including cold cleaning and vapor degreasing and defluxing. Typically, these involve a bath of solvent. SNAP categorizes industrial cleaning as precision cleaning, electronics cleaning, or metals cleaning.

As clarified in a SNAP Notice (63 FR 9151; February 24, 1998), the three end-uses are defined as follows:

Precision Cleaning

Precision cleaning is the cleaning of any components or surfaces of any composition for which an extremely high level of cleanliness is necessary to ensure satisfactory performance during the manufacturing process or in final consumption. This end-use is characterized as very high value based on non-cost criteria, including high value products, protection or safeguarding of human life, compatibility concerns with plastics, temperature and mechanical stress limitations, precision mechanical assemblies/components with demanding machining tolerances or complex geometries, and base or mix of metals readily pitted, corroded, eroded, or otherwise compromised. Examples of “high-performance electronics and precision cleaning” include cleaning of high-value added parts for aerospace, military, or medical applications such as precision ball bearings for navigational devices, automotive safety circuits (e.g., airbag deployment and braking systems), or medical devices.

Electronics Cleaning

Electronics cleaning is the removal of flux residues from wiring assemblies on printed circuit boards after a soldering operation has been completed. It is considered a high-value end-use where performance is critical.

Metals Cleaning

Metals cleaning is defined as the removal of a wide variety of contaminants from metal objects during a manufacturing or maintenance process. At each stage in the process, contaminants must be removed from the piece to ensure a clean metal surface for the next step in the production process or for final consumption. These metal objects range from fully assembled aircraft down to small metal parts stamped out in high volume. The contaminants are often greases, cutting oils, coatings, large particles, and metal chips.

Non-aerosol solvent cleaning applications that EPA has chosen not to subject to SNAP include:

- Bearer media (e.g., a substitute for CFC-113 or HCFC-141b in depositing lubricants on medical catheters)

- Plasma etching

- Mold release agents for non-aerosol applications

- Motor vehicle air-conditioning (MVAC) flushing

- Hand wiping, hand cleaning, and maintenance cleaning as a non-aerosol

- Dry cleaning of textiles

- Flushing of oxygen systems

If EPA determines in the future that the use of substitutes in any of these applications poses a significant environmental or health risk, EPA could begin requiring SNAP review and requirements for solvents used in these applications.