Basic Information about Landfill Gas

On this page:

Landfill gas (LFG) is a natural byproduct of the decomposition of organic material in landfills. LFG is composed of roughly 50 percent methane (the primary component of natural gas), 50 percent carbon dioxide (CO2) and a small amount of non-methane organic compounds. Methane is a potent greenhouse gas with a global warming potential that is 25 times greater than CO2.

Methane Emissions from Landfills

Municipal solid waste (MSW) landfills are the third-largest source of human-related methane emissions in the United States, accounting for approximately 18.2 percent of these emissions in 2014. At the same time, methane emissions from landfills represent a lost opportunity to capture and use a significant energy resource.

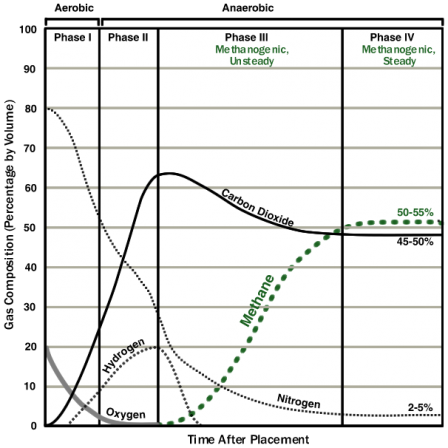

When MSW is first deposited in a landfill, it undergoes an aerobic (with oxygen) decomposition stage when little methane is generated. Then, typically within less than 1 year, anaerobic conditions are established and methane-producing bacteria begin to decompose the waste and generate methane.

- View a diagram that illustrates the changes in typical LFG composition after waste placement

- Learn more in Chapter 1. Landfill Gas Energy Basics from LMOP's LFG Energy Project Development Handbook

In October 2009, EPA issued a rule (40 CFR Part 98) that requires the reporting of greenhouse gas emissions from large sources and suppliers in the United States, and is intended to collect accurate and timely emissions data to inform future policy decisions.

Annually, EPA issues an inventory report to present the U.S. government's estimates of U.S. human-related greenhouse gas emissions and sinks for each year since 1990. Emissions from the waste sector as well as other sectors are presented in this inventory.

Converting Landfill Gas to Energy

Instead of escaping into the air, LFG can be captured, converted, and used as an energy source. Using LFG helps to reduce odors and other hazards associated with LFG emissions, and it helps prevent methane from migrating into the atmosphere and contributing to local smog and global climate change. Learn more about the benefits of using LFG.

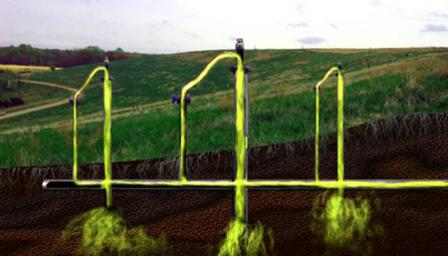

LFG is extracted from landfills using a series of wells and a blower/flare (or vacuum) system. This system directs the collected gas to a central point where it can be processed and treated depending upon the ultimate use for the gas. From this point, the gas can be flared, used to generate electricity, replace fossil fuels in industrial and manufacturing operations, or upgraded to pipeline-quality gas where the gas may be used directly or processed into an alternative vehicle fuel. Diagrams and photographs of the various components of an LFG collection system:

- LFG well

- LFG wellhead

- LFG wells and collection piping

- LFG system

- LFG treatment/blower/flare station

- LFG flare

Several options are available for converting LFG to energy. Below are descriptions of some of the typical project types.

Electricity Generation

About three-fourths of currently operational projects in the United States generate electricity from LFG. Electricity for onsite use or sale to the grid can be generated using a variety of technologies, including internal combustion engines, turbines, microturbines, and fuel cells. The vast majority of projects use internal combustion (reciprocating) engines or turbines, with microturbine technology being used at smaller landfills and in niche applications.

Direct Use

Directly using LFG to offset the use of another fuel (for example, natural gas, coal, or fuel oil) is occurring in about one-fourth of the currently operational projects. LFG can be used directly in a boiler, dryer, kiln, greenhouse, or other thermal application. LFG can also be used directly to evaporate leachate. Innovative direct uses include firing pottery and glass-blowing kilns; powering and heating greenhouses; and evaporating waste paint. Current industries using LFG include auto manufacturing, chemical production, food processing, pharmaceuticals, cement and brick manufacturing, wastewater treatment, consumer electronics and products, paper and steel production, and prisons and hospitals.

Cogeneration

Cogeneration, also known as combined heat and power or CHP, projects use LFG to generate both electricity and thermal energy, usually in the form of steam or hot water. Several cogeneration projects have been installed at industrial operations, using engines or turbines. The efficiency gains of capturing the thermal energy in addition to electricity generation can make these projects very attractive.

Alternative Fuels

Production of alternative fuels from LFG is an emerging area. LFG has been successfully delivered to natural gas pipeline systems as both a high-Btu and medium-Btu fuel. LFG is also being used to produce the equivalent of compressed natural gas (CNG) or liquefied natural gas (LNG) for use in vehicles.