Drinking Water Treatment Technology Unit Cost Models and Overview of Technologies

Drinking water treatment technology unit cost models

Federal laws and executive orders require EPA to estimate compliance costs for new drinking water standards. The three major components of compliance costs are:

- Treatment

- Monitoring

- Administrative costs

Treatment technologies remove or destroy pollutants (such as arsenic, disinfection byproducts, and waterborne pathogens).

To estimate treatment costs, EPA developed several engineering models using a bottom-up approach known as work breakdown structure (WBS). The WBS models:

- Derive system-level costs

- Provide EPA with comprehensive, flexible and transparent tools to help estimate treatment costs

Each WBS engineering model contains a work breakdown for a particular treatment process. Engineering equations estimate equipment requirements given user-defined inputs such as design and average flow. Each model has many design assumptions (such as redundancy requirements). The models provide unit cost and total cost information by component.

The models also contain estimates of:

- Add-on costs (such as permits, pilot studies and land acquisition)

- Indirect capital costs (such as site work and contingencies)

- Annual operation and maintenance costs

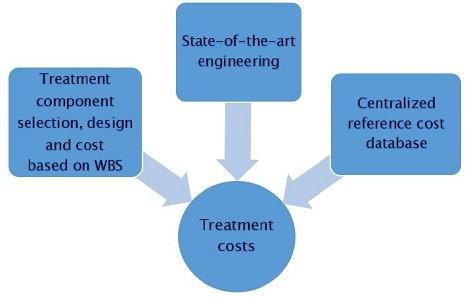

Figure 1 shows the structural features used to generate treatment costs in the WBS models.

Figure 1. Structural features used to generate treatment costs in WBS models

Figure 1. Structural features used to generate treatment costs in WBS models

The WBS models integrate these features into a series of worksheets in a Microsoft® Excel workbook for each technology. An input sheet allows users to define parameters (such as system design and average flows, target contaminant, and raw water quality). Critical design assumptions generally reflect engineering practices. Users can revise these values to reflect site-specific requirements.

General documentation for the WBS approach and common features may be found in the Work Breakdown Structure-Based Cost Models for Drinking Water Treatment Technologies (PDF)(145 pp, 2MB, About PDF).

Particularly useful sections of this report include:

- Chapter 1. Introduction

- Chapter 2. WBS Model Overview

- Appendix A. Valves, Instrumentation and System Controls

- Appendix B. Building Construction Costs

- Appendix C. Residuals Management Costs

- Appendix D. Indirect Capital Costs.

WBS cost models are available to the public for the following treatment technologies:

- Granular Activated Carbon (GAC) (XLSM)(1 pg, 940 K)

(919 K) is a porous adsorption media that is useful for the removal of:

- taste and odor compounds

- natural organic matter

- volatile organic compounds

- synthetic organic compounds

- disinfection byproduct precursors

- Packed Tower Aeration (PTA) (XLSM)(1 pg, 737 K)

(720K) uses towers filled with a packing media to mechanically increase the area of water exposed to non-contaminated air. PTA reduces the concentration of volatile contaminants including:

- volatile organic compounds

- disinfection byproducts

- hydrogen sulfide

- carbon dioxide

- other taste-and-odor-producing compounds

- Multi-Stage Bubble Aeration (MSBA) (XLSM)(1 pg, 479 K)

(468K) uses basins and diffusers to release small air bubbles, causing volatile contaminants to pass from the water into the air. MSBA:

- removes volatile organic compounds from source water

- improves the taste and odor of the water

Overview of technologies

What is granular activated carbon?

Granular activated carbon (GAC) is a porous adsorption media with extremely high internal surface area. GACs are manufactured from a variety of raw materials with porous structures including:

- bituminous coal

- lignite coal

- peat

- wood

- coconut shells

Physical and/or chemical manufacturing processes are applied to these raw materials to create and/or enlarge pores. This results in a porous structure with a large surface area per unit mass.

Why is it useful?

GAC is useful for the removal of taste- and odor-producing compounds, natural organic matter, volatile organic compounds (VOCs), synthetic organic compounds and disinfection byproduct precursors. Organic compounds with high molecular weights are readily adsorbable.

Treatment capacities for different contaminants vary depending on the properties of the different GACs, which in turn vary widely depending on the raw materials and manufacturing processes used.

What are the advantages of using GAC?

GAC is a proven technology with high removal efficiencies (up to 99.9%) for many VOCs, including trichloroethylene (TCE) and tetrachloroethylene (PCE). In most cases, GAC can remove target contaminants to concentrations below 1 µg/l. Another advantage is that regenerative carbon beds allow for easy recovery of the adsorption media.

What are the disadvantages of using GAC?

The media has to be removed and replaced or regenerated when GAC capacity is exhausted. In some cases, disposal of the media may require a special hazardous waste handling permit. Other adsorbable contaminants in the water can reduce GAC capacity for a target contaminant.

How can the WBS model for GAC be used?

The work breakdown structure (WBS) model can estimate costs for two types of GAC systems where:

- the GAC bed is contained in pressure vessels in a treatment configuration similar to that used for other adsorption media (for example, activated alumina), referred to as pressure GAC

- the GAC bed is contained in open concrete basins in a treatment configuration similar to that used in the filtration step of conventional or direct filtration, referred to as gravity GAC

The WBS model for GAC includes standard designs to estimate costs for treatment of a number of different contaminants, including atrazine and various VOCs. The WBS model can also be used to estimate the cost of GAC treatment for removal of other contaminants.

To simulate the use of GAC for treatment of other contaminants, users will need to adjust default inputs (for example, bed volumes before breakthrough, bed depth) and, potentially, critical design assumptions (for example, minimum and maximum loading rates).

Where can I find more information on GAC?

Chapter 3 of the technical report Work Breakdown Structure-Based Cost Models for Drinking Water Treatment Technologies discusses GAC technology in detail.

What is packed tower aeration?

Aeration processes, in general, transfer contaminants from water to air. Packed tower aeration (PTA) uses towers filled with a packing media designed to mechanically increase the area of water exposed to non-contaminated air. Water falls from the top of the tower through the packing media while a blower forces air upwards through the tower. In the process, volatile contaminants pass from the water into the air.

Why is it useful?

PTA is useful for removing volatile contaminants including:

- Volatile organic compounds (VOCs)

- Disinfection byproducts

- Hydrogen sulfide

- Carbon dioxide

- Other taste- and odor-producing compounds

The more volatile the contaminant, the more easily PTA will remove it. PTA readily removes the most volatile contaminants, such as vinyl chloride. With sufficient tower height and air flow, PTA can even remove somewhat less volatile contaminants, such as 1,2-dichloroethane.

What are the advantages of using PTA?

PTA is a proven technology and can achieve high removal efficiencies (99 percent or greater) for most VOCs. PTA removal efficiency is independent of starting concentration. Therefore, it can remove most volatile contaminants to concentrations below 1 µg/L. PTA generates no liquid or solid waste residuals for disposal.

What are the disadvantages of using PTA?

Depending on the location and conditions, air quality regulations might require the use of air pollution control devices with PTA, increasing the technology cost. PTA uses tall towers that could be considered unsightly in some communities. Under certain water quality conditions, scaling or fouling of the packing media can occur if precautions are not taken.

How can the WBS model for PTA be used?

The work breakdown structure (WBS) model for PTA includes standard designs to estimate costs for treatment of a number of different contaminants, including methyl tertiary-butyl ether (MTBE) and various VOCs. However, the WBS model can be used to estimate the cost of PTA treatment for removal of other contaminants as well.

To simulate the use of PTA for treatment of other contaminants, users will need to adjust default inputs (for example, Henry’s coefficient, molecular weight) and, potentially, critical design assumptions (for example, minimum and maximum packing height).

Where can I find more information on PTA?

Chapter 4 of the technical report Work Breakdown Structure-Based Cost Models for Drinking Water Treatment Technologies discusses PTA technology in detail.

What is multi-stage bubble aeration?

Aeration processes, in general, transfer contaminants from water to air. Multi-stage bubble aeration (MSBA) uses shallow basins that are divided into smaller compartments, or stages, using baffles.

Inside each stage, diffusers (consisting of perforated pipes or porous plates) release small air bubbles that rise through the water. The bubbles and their resulting turbulence cause volatile contaminants to pass from the water into the air.

Why is it useful?

MSBA is useful for removing volatile contaminants including:

- Volatile organic compounds (VOCs)

- Hydrogen sulfide

- Carbon dioxide

- Other taste- and odor-producing compounds

The more volatile the contaminant, the more easily MSBA will remove it. Vendors supply MSBA in skid-mounted, pre-packaged systems that can be particularly suitable for small systems.

What are the advantages of using MSBA?

MSBA is a proven technology. In recent EPA pilot tests, MSBA achieved high removal efficiencies (98 percent to greater than 99 percent) for most VOCs, removing them to concentrations below 1 µg/L. MSBA is a low-profile aeration technology that does not require tall, potentially unsightly towers. MSBA generates no liquid or solid waste residuals for disposal.

What are the disadvantages of using MSBA?

Depending on the location and conditions, air quality regulations might require the use of air pollution control devices with MSBA, increasing the technology cost.

MSBA is less efficient at removing contaminants than packed tower aeration, requiring high air flow rates to remove the most recalcitrant VOCs. Treating large water flows with MSBA can require a large number of basins. This might not be practical for large systems.

How can the WBS model for MSBA be used?

The work breakdown structure (WBS) model for MSBA model includes standard designs for the treatment of a number of contaminants, including various VOCs. However, the WBS model can be used to estimate the cost of MSBA treatment for removal of other volatile contaminants as well.

To simulate the use of MSBA for treatment of other contaminants, users will need to adjust default inputs (for example, air-to-water ratio, number of stages) and, potentially, critical design assumptions (for example, maximum air surface intensity).

Where can I find more information on MSBA?

Chapter 5 of the technical report Work Breakdown Structure-Based Cost Models for Drinking Water Treatment Technologies discusses MSBA technology in detail.