Mold Remediation in Schools and Commercial Buildings Guide

The content on this web page is based on the publication Mold Remediation in Schools and Commercial Buildings[EPA 402-K-01-001, Reprinted September 2008]. Updates have been made to some resources and links.

Introduction

Concern about indoor exposure to mold has been increasing as the public becomes aware that exposure to mold can cause a variety of health effects and symptoms, including allergic reactions. This document presents guidelines for the remediation/cleanup of mold and moisture problems in schools and commercial buildings; these guidelines include measures designed to protect the health of building occupants and remediators. It has been designed primarily for:

- Building managers

- Custodians

- Others who are responsible for commercial building and school maintenance

It should serve as a reference for potential mold and moisture remediators. Using this document, individuals with little or no experience with mold remediation should be able to make a reasonable judgment as to whether the situation can be handled in-house. It will help those in charge of maintenance to evaluate an in-house remediation plan or a remediation plan submitted by an outside contractor1. Contractors and other professionals who respond to mold and moisture situations in commercial buildings and schools may also want to refer to these guidelines.

Molds can be found almost anywhere; they can grow on virtually any organic substance, as long as moisture and oxygen are present. There are molds that can grow on wood, paper, carpet, foods, and insulation. When excessive moisture accumulates in buildings or on building materials, mold growth will often occur, particularly if the moisture problem remains undiscovered or unaddressed. It is impossible to eliminate all mold and mold spores in the indoor environment. However, mold growth can be controlled indoors by controlling moisture indoors.

Molds reproduce by making spores that usually cannot be seen without magnification. Mold spores waft through the indoor and outdoor air continually. When mold spores land on a damp spot indoors, they may begin growing and digesting whatever they are growing on in order to survive. Molds gradually destroy the things they grow on.

Many types of molds exist. All molds have the potential to cause health effects. Molds can produce allergens that can trigger allergic reactions or even asthma attacks in people allergic to mold. Others are known to produce potent toxins and/or irritants. Potential health concerns are an important reason to prevent mold growth and to remediate/clean up any existing indoor mold growth.

Since mold requires water to grow, it is important to prevent moisture problems in buildings. Moisture problems can have many causes, including uncontrolled humidity. Some moisture problems in buildings have been linked to changes in building construction practices during the 1970s, 80s and 90s. Some of these changes have resulted in buildings that are tightly sealed, but may lack adequate ventilation, potentially leading to moisture buildup. Building materials, such as drywall, may not allow moisture to escape easily. Moisture problems may include:

- Roof leaks

- Landscaping or gutters that direct water into or under the building

- Unvented combustion appliances

- Delayed maintenance or insufficient maintenance are also associated with moisture problems in schools and large buildings

Moisture problems in portable classrooms and other temporary structures have frequently been associated with mold problems. For more information see IAQ Design Tools for Schools - Portable Classrooms.

When mold growth occurs in buildings, adverse health problems may be reported by some building occupants, particularly those with allergies or respiratory problems. Remediators should avoid exposing themselves and others to mold-laden dusts as they conduct their cleanup activities. Caution should be used to prevent mold and mold spores from being dispersed throughout the air where they can be inhaled by building occupants.

Footnotes:

1: If you choose to use outside contractors or professionals, make sure they have experience cleaning up mold, check their references and have them follow the recommendations presented in this document, the guidelines of the American Conference of Government Industrial Hygienists (ACGIH) and/or guidelines from other professional organizations. See Resources List

Prevention

The key to mold control is moisture control. Solve moisture problems before they become mold problems!

Mold Prevention Tips

- Fix leaky plumbing and leaks in the building envelope as soon as possible.

- Watch for condensation and wet spots. Fix source(s) of moisture problem(s) as soon as possible.

- Prevent moisture due to condensation by increasing surface temperature or reducing the moisture level in air (humidity). To increase surface temperature, insulate or increase air circulation. To reduce the moisture level in air, repair leaks, increase ventilation (if outside air is cold and dry), or dehumidify (if outdoor air is warm and humid).

- Keep heating, ventilation and air conditioning (HVAC) drip pans clean, flowing properly and unobstructed.

- Vent moisture-generating appliances, such as dryers, to the outside where possible.

- Maintain low indoor humidity, below 60% relative humidity (RH), ideally 30-50%, if possible.

- Perform regular building/HVAC inspections and maintenance as scheduled.

- Clean and dry wet or damp spots within 48 hours.

- Don't let foundations stay wet. Provide drainage and slope the ground away from the foundation.

Investigating, Evaluating and Remediating Moisture and Mold Problems

- Mold Remediation - Key Steps

- Plan the Remediation Before Starting Work

- Heating, Ventilation, and Air-Conditioning (HVAC) System

- Hidden Mold

- Remediation

- Table 1: Water Damage Cleanup and Mold Prevention

- Table 2: Mold Remediation Guidelines

- Cleanup Methods

- Personal Protective Equipment (PPE)

- Containment

- Equipment

- Sampling

- How Do You Know When You Have Finished Remediation/Cleanup?

- Footnotes

Safety Tips While Investigating and Evaluating Mold and Moisture Problems

- Do not touch mold or moldy items with bare hands.

- Do not get mold or mold spores in your eyes.

- Do not breathe in mold or mold spores.

- Consult Table 2 and text for Personal Protective Equipment (PPE) and containment guidelines.

- Consider using PPE when disturbing mold. The minimum PPE is an N-95 respirator, gloves and eye protection.

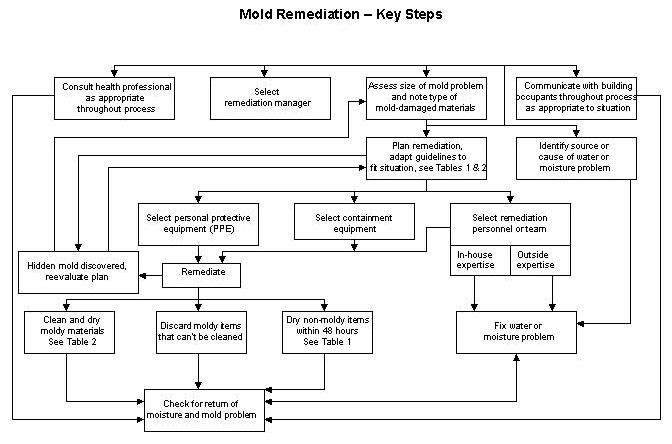

Mold Remediation - Key Steps

- Consult health professional as appropriate throughout process

- Select remediation manager

- Assess size of mold problem and note type of mold-damaged materials

- Communicate with building occupants throughout process as appropriate to situation

- Identify source or cause of water or moisture problem

- Plan remediation, adapt guidelines to fit situation, see Table 1 Table 2

- Select personal protective equipment (PPE)

- Select containment equipment

- Select remediation personnel or team

- Choose between outside expertise or in-house expertise

- Remediate

- Fix water or moisture problem

- Clean and dry moldy materials See Table 2

- Discard moldy items that can't be cleaned

- Dry non-moldy items within 48 hours See Table 1

- Check for return of moisture and mold problem

- If hidden mold is discovered, reevaluate plan

Mold Areas Encountered During an Investigation

Plan the Remediation Before Starting the Work

Remediation Plan

Assess the size of the mold and/or moisture problem and the type of damaged materials before planning the remediation work. Select a remediation manager for medium or large jobs (or small jobs requiring more than one person). The remediation plan should include steps to fix the water or moisture problem, or the problem may reoccur. The plan should cover the use of appropriate Personal Protective Equipment (PPE) and include steps to carefully contain and remove moldy building materials to avoid spreading the mold.(2) A remediation plan may vary greatly depending on the size and complexity of the job, and may require revision if circumstances change or new facts are discovered.

The remediation manager's highest priority must be to protect the health and safety of the building occupants and remediators. It is also important to communicate with building occupants when mold problems are identified.(3) In some cases, especially those involving large areas of contamination, the remediation plan may include temporary relocation of some or all of the building occupants.

The decision to relocate occupants should consider:

- The size and type of the area affected by mold growth

- The type and extent of health effects reported by the occupants

- The potential health risks that could be associated with debris

- The amount of disruption likely to be caused by remediation activities

If possible, remediation activities should be scheduled during off-hours when building occupants are less likely to be affected.

Remediators, particularly those with health-related concerns, may wish to check with their doctors or health care professionals before working on mold remediation or investigating potentially moldy areas. If you have any doubts or questions, you should consult a health professional before beginning a remediation project.

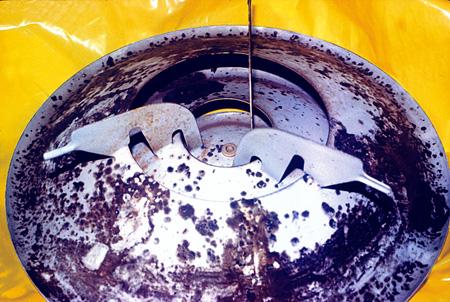

Heating, Ventilation, and Air-Conditioning (HVAC) System

Do not run the HVAC system if you know or suspect that it is contaminated with mold. If you suspect that it may be contaminated (it is part of an identified moisture problem, for instance, or there is mold growth near the intake to the system), consult,

Hidden Mold

In some cases, indoor mold growth may not be obvious. It is possible that mold may be growing on hidden surfaces, such as:

- The back side of dry wall

- Wallpaper

- Paneling

- The top of ceiling tiles

- The underside of carpets and pads

Possible locations of hidden mold can include:

- Pipe chases and utility tunnels (with leaking or condensing pipes)

- Walls behind furniture (where condensation forms)

- Condensate drain pans inside air handling units

- Porous thermal or acoustic liners inside ductwork

- Roof materials above ceiling tiles (due to roof leaks or insufficient insulation)

Some building materials, such as dry wall with vinyl wallpaper over it or wood paneling, may act as vapor barriers, (5) trapping moisture underneath their surfaces and thereby providing a moist environment where mold can grow. You may suspect hidden mold if a building smells moldy, but you cannot see the source, or if you know there has been water damage and building occupants are reporting health problems. Investigating hidden mold problems may be difficult and will require caution when the investigation involves disturbing potential sites of mold growth—make sure to use personal protective equipment (PPE). For example, removal of wallpaper can lead to a massive release of spores from mold growing on the underside of the paper. If you believe that you may have a hidden mold problem, you may want to consider hiring an experienced professional. If you discover hidden mold, you should revise your remediation plan to account for the total area affected by mold growth.

Remediation

- Fix the water or humidity problem. Complete and carry out repair plan if appropriate. Revise and/or carry out maintenance plan if necessary. Revise remediation plan as necessary, if more damage is discovered during remediation. For additional information see:

- Continue to communicate with building occupants, as appropriate to the situation. Be sure to address all concerns.

- Completely clean up mold and dry water-damaged areas. Select appropriate cleaning and drying methods for damaged/contaminated materials. Carefully contain and remove moldy building materials. Use appropriate Personal Protective Equipment (PPE). Arrange for outside professional support if necessary.

Table 1: Water Damage Cleanup and Mold Prevention (6)

Table 1 presents strategies to respond to water damage within 24-48 hours. These guidelines are designed to help avoid the need for remediation of mold growth by taking quick action before growth starts. If mold growth is found on the materials listed in Table 1, refer to Table 2 for guidance on remediation. Depending on the size of the area involved and resources available, professional assistance may be needed to dry an area quickly and thoroughly. See:

Table 2: Mold Remediation Guidelines (7)

Table 2 presents remediation guidelines for building materials that have or are likely to have mold growth. The guidelines in Table 2 are designed to protect the health of occupants and cleanup personnel during remediation. These guidelines are based on the area and type of material affected by water damage and/or mold growth. Please note that these are guidelines; some professionals may prefer other cleaning methods. See Table 2

If you are considering cleaning your ducts as part of your remediation plan, you should consult EPA's publication entitled, "Should You Have the Air Ducts In Your Home Cleaned?" (8). If possible, remediation activities should be scheduled during off-hours when building occupants are less likely to be affected. See:

Although the level of personal protection suggested in these guidelines is based on the total surface area contaminated and the potential for remediator and/or occupant exposure, professional judgment should always play a part in remediation decisions. These remediation guidelines are based on the size of the affected area to make it easier for remediators to select appropriate techniques, not on the basis of health effects or research showing there is a specific method appropriate at a certain number of square feet. The guidelines have been designed to help construct a remediation plan. The remediation manager will then use professional judgment and experience to adapt the guidelines to particular situations. When in doubt, caution is advised. Consult an experienced mold remediator for more information.

A more cautious or conservative approach to remediation is indicated in cases in which:

- A particularly toxic mold species has been identified or is suspected

- When extensive hidden mold is expected (such as behind vinyl wallpaper or in the HVAC system)

- When the chances of the mold becoming airborne are estimated to be high

- Sensitive individuals (e.g., those with severe allergies or asthma) are present

Always make sure to protect remediators and building occupants from exposure to mold.

Cleanup Methods

Molds Can Damage Building Materials and Furnishings

Mold can eventually cause structural damage to a school or large building, if a mold/moisture problem remains unaddressed for a long time. In the case of a long-term roof leak, for example, molds can weaken floors and walls as the molds feed on wet wood. If you suspect that mold has damaged building integrity, you should consult a structural engineer or other professional with expertise in this area.

A variety of mold cleanup methods are available for remediating damage to building materials and furnishings caused by moisture control problems and mold growth. The specific method or group of methods used will depend on the type of material affected, as presented in Table 2. Please note that professional remediators may use some methods not covered in these guidelines; absence of a method in the guidelines does not necessarily mean that it is not useful. (9). See Table 2

- Method 1: Wet Vacuum

Method 1: Wet Vacuum

Wet vacuums are vacuum cleaners designed to collect water. They can be used to remove water from floors, carpets and hard surfaces where water has accumulated. They should not be used to vacuum porous materials, such as gypsum board. They should be used only when materials are still wet — wet vacuums may spread spores if sufficient liquid is not present. The tanks, hoses and attachments of these vacuums should be thoroughly cleaned and dried after use since mold and mold spores may stick to the surfaces.

- Method 2: Damp Wipe

Method 2: Damp Wipe

Whether dead or alive, mold is allergenic, and some molds may be toxic. Mold can generally be removed from nonporous (hard) surfaces by wiping or scrubbing with water, or water and detergent. It is important to dry these surfaces quickly and thoroughly to discourage further mold growth. Instructions for cleaning surfaces, as listed on product labels, should always be read and followed. Porous materials that are wet and have mold growing on them may have to be discarded. Since molds will infiltrate porous substances and grow on or fill in empty spaces or crevices, the mold can be difficult or impossible to remove completely.

- Method 3: HEPA Vacuum

Method 3: HEPA Vacuum

HEPA (High-Efficiency Particulate Air) vacuums are recommended for final cleanup of remediation areas after materials have been thoroughly dried and contaminated materials removed. HEPA vacuums are also recommended for cleanup of dust that may have settled on surfaces outside the remediation area. Care must be taken to assure that the filter is properly seated in the vacuum so that all the air must pass through the filter. When changing the vacuum filter, remediators should wear PPE to prevent exposure to the mold that has been captured. The filter and contents of the HEPA vacuum must be disposed of in well-sealed plastic bags.

- Method 4: Remove Damaged Materials and Seal in Plastic Bags

Method 4: Discard — Remove Damaged Materials and Seal in Plastic Bags

Building materials and furnishings that are contaminated with mold growth and are not salvageable should be double-bagged using 6-mil polyethylene sheeting. These materials can then usually be discarded as ordinary construction waste. It is important to package mold-contaminated materials in sealed bags before removal from the containment area to minimize the dispersion of mold spores throughout the building. Large items that have heavy mold growth should be covered with polyethylene sheeting and sealed with duct tape before they are removed from the containment area.

Personal Protective Equipment (PPE)

If the remediation job disturbs mold and mold spores become airborne, then the risk of respiratory exposure goes up. Actions that are likely to stir up mold include:

- Breakup of moldy porous materials such as wallboard

- Invasive procedures used to examine or remediate mold growth in a wall cavity

- Actively stripping or peeling wallpaper to remove it

- Using fans to dry items

The primary function of Personal Protective Equipment (PPE) is to avoid inhaling mold and mold spores and to avoid mold contact with the skin or eyes. The following sections discuss the different types of PPE that can be used during remediation activities. Please note that all individuals using certain PPE equipment, such as half-face or full-face respirators, must be trained, must have medical clearance and must be fit-tested by a trained professional. In addition, the use of respirators must follow a complete respiratory protection program as specified by the Occupational Safety and Health Administration. For more information see Resources List.

- Skin and Eye Protection

Skin and Eye Protection

Gloves are required to protect the skin from contact with mold allergens (and in some cases mold toxins) and from potentially irritating cleaning solutions. Long gloves that extend to the middle of the forearm are recommended. The glove material should be selected based on the type of materials being handled. If you are using a biocide (such as chlorine bleach) or a strong cleaning solution, you should select gloves made from:

- Natural rubber

- Neoprene

- Nitrile

- Polyurethane

- PVC

If you are using a mild detergent or plain water, ordinary household rubber gloves may be used. To protect your eyes, use properly fitted goggles or a full-face respirator with HEPA filter. Goggles must be designed to prevent the entry of dust and small particles. Safety glasses or goggles with open vent holes are not acceptable.

- Respiratory Protection

Respiratory Protection

Respirators protect cleanup workers from inhaling airborne mold, mold spores and dust.

- Minimum: When cleaning up a small area affected by mold, you should use an N-95 respirator. This device:

- Covers the nose and mouth

- Will filter out 95% of the particulates in the air

- Is available in most hardware stores

- Limited: Limited PPE includes use of a half-face or full-face air purifying respirator (APR) equipped with a HEPA filter cartridge. These respirators contain both inhalation and exhalation valves that filter the air and ensure that it is free of mold particles. Note that half-face APRs do not provide eye protection. In addition, the HEPA filters do not remove vapors or gases. You should always use respirators approved by the National Institute for Occupational Safety and Health. See Resources List.

- Full: In situations in which high levels of airborne dust or mold spores are likely or when intense or long-term exposures are expected (e.g., the cleanup of large areas of contamination), a full-face, powered air purifying respirator (PAPR) is recommended. Full-face PAPRs use a blower to force air through a HEPA filter. The HEPA-filtered air is supplied to a mask that covers the entire face or a hood that covers the entire head. The positive pressure within the hood prevents unfiltered air from entering through penetrations or gaps. Individuals must be trained to use their respirators before they begin remediation. The use of these respirators must be in compliance with OSHA regulations. See Resources List.

- Minimum: When cleaning up a small area affected by mold, you should use an N-95 respirator. This device:

- Disposable Protective Clothing

Disposable Protective Clothing

Disposable clothing is recommended during a medium or large remediation project to prevent the transfer and spread of mold to clothing and to eliminate skin contact with mold.

- Limited: Disposable paper overalls can be used.

- Full: Mold-impervious disposable head and foot coverings, and a body suit made of a breathable material, such as TYVEK®, should be used. All gaps, such as those around ankles and wrists, should be sealed (many remediators use duct tape to seal clothing).

Containment

The purpose of containment during remediation activities is to limit release of mold into the air and surroundings, in order to minimize the exposure of remediators and building occupants to mold. Mold and moldy debris should not be allowed to spread to areas in the building beyond the contaminated site.

The two types of containment recommended in Table 2 are limited and full. The larger the area of moldy material, the greater the possibility of human exposure and the greater the need for containment. In general, the size of the area helps determine the level of containment. However, a heavy growth of mold in a relatively small area could release more spores than a lighter growth of mold in a relatively large area. Choice of containment should be based on professional judgment.(10) The primary object of containment should be to prevent occupant and remediator exposure to mold. See Table 2

- Limited Containment

Limited Containment

Limited containment is generally recommended for areas involving between 10 and 100 square feet (ft2) of mold contamination. The enclosure around the moldy area should consist of a single layer of 6-mil, fire-retardant polyethylene sheeting. The containment should have a slit entry and covering flap on the outside of the containment area. For small areas, the polyethylene sheeting can be affixed to floors and ceilings with duct tape. For larger areas, a steel or wooden stud frame can be erected and polyethylene sheeting attached to it. To minimize the migration of contaminants to other parts of the building, certain places within the containment area must be sealed with polyethylene sheeting, including:

- All supply and air vents

- Doors

- Chases

- Risers

Heavy mold growth on ceiling tiles may impact HVAC systems if the space above the ceiling is used as a return air plenum. In this case, containment should be installed from the floor to the ceiling deck, and the filters in the air handling units serving the affected area may have to be replaced once remediation is finished.

The containment area must be maintained under negative pressure relative to surrounding areas. This will ensure that contaminated air does not flow into adjacent areas. This can be done with a HEPA-filtered fan unit exhausted outside of the building. For small, easily contained areas, an exhaust fan ducted to the outdoors can also be used. The surfaces of all objects removed from the containment area should be remediated/cleaned prior to removal. The remediation guidelines outlined in Table 2 can be implemented when the containment is completely sealed and is under negative pressure relative to the surrounding area. See Table 2

- Full Containment

Full Containment

Full containment is recommended for the cleanup of mold-contaminated surface areas greater than 100 ft2 or in any situation in which it appears likely that the occupant space would be further contaminated without full containment. Double layers of polyethylene should be used to create a barrier between the moldy area and other parts of the building. A decontamination chamber or airlock should be constructed for entry into and exit from the remediation area. The entryways to the airlock from the outside and from the airlock to the main containment area should consist of a slit entry with covering flaps on the outside surface of each slit entry. The chamber should be large enough to hold a waste container and allow a person to put on and remove PPE. All contaminated PPE, except respirators, should be placed in a sealed bag while in this chamber. Respirators should be worn until remediators are outside the decontamination chamber. PPE must be worn throughout the final stages of HEPA vacuuming and damp-wiping of the contained area. PPE must also be worn during HEPA vacuum filter changes or cleanup of the HEPA vacuum.

Equipment

- Moisture Meters

Moisture Meters: Measure/Monitor Moisture Levels in Building Materials

Moisture meters may be helpful for measuring the moisture content in a variety of building materials following water damage. They can also be used to monitor the process of drying damaged materials. These direct reading devices have a thin probe which can be inserted into the material to be tested or can be pressed directly against the surface of the material. Moisture meters can be used on materials such as carpet, wallboard, wood, brick and concrete.

- Humidity Gauges or Meters

Humidity Gauges or Meters: Monitor Moisture Levels in the Air

Humidity meters can be used to monitor humidity indoors. Inexpensive ($50) models are available that monitor both temperature and humidity.

- Humidistat

Humidistat: Turns on HVAC System at Specific Relative Humidity (RH)

A humidistat is a control device that can be connected to the HVAC system and adjusted so that, if the humidity level rises above a set point, the HVAC system will automatically come on.

- HVAC System Filter

HVAC System Filter: Filters Outdoor Air

Use high-quality filters in your HVAC system during remediation. Consult an engineer for the appropriate efficiency for your specific HVAC system and consider upgrading your filters if appropriate. Conventional HVAC filters are typically not effective in filtering particles the size of mold spores. Consider upgrading to a filter with a minimum efficiency of 50 to 60% or a rating of MERV 8, as determined by Test Standard 52.2 of the American Society of Heating, Refrigerating and Air Conditioning Engineers. Remember to change filters regularly and change them following any remediation activities.

Sampling

Is sampling for mold needed? In most cases, if visible mold growth is present, sampling is unnecessary. You may consider sampling as part of your site evaluation in specific instances, such as:

- Cases where litigation is involved

- The source(s) of the mold contamination is unclear

- Health concerns are a problem

Surface sampling may also be useful in order to determine if an area has been adequately cleaned or remediated. Sampling should be done only after developing a sampling plan that includes a confirmable theory regarding suspected mold sources and routes of exposure. Figure out what you think is happening and how to prove or disprove it before you sample.

If you do not have extensive experience and/or are in doubt about sampling, consult an experienced professional. This individual can help you decide if sampling for mold is useful and/or needed, and will be able to carry out any necessary sampling. It is important to remember that the results of sampling may have limited use or application. Sampling may help locate the source of mold contamination, identify some of the mold species present and differentiate between mold and soot or dirt. Pre- and post-remediation sampling may also be useful in determining whether remediation efforts have been effective. After remediation, the types and concentrations of mold in indoor air samples should be similar to what is found in the local outdoor air. Since no EPA or other Federal threshold limits have been set for mold or mold spores, sampling cannot be used to check a building's compliance with Federal mold standards.

Sampling for mold should be conducted by professionals with specific experience in designing mold sampling protocols, sampling methods and interpretation of results. Sample analysis should follow analytical methods recommended by the American Industrial Hygiene Association (AIHA), the American Conference of Governmental Industrial Hygienists (ACGIH), or other professional guidelines (see Resources List). Types of samples include:

- Air samples

- Surface samples

- Bulk samples (chunks of carpet, insulation, wall board, etc.)

- Water samples from condensate drain pans or cooling towers

A number of pitfalls may be encountered when inexperienced personnel conduct sampling:

- They may take an inadequate number of samples

- There may be inconsistency in sampling protocols

- The samples may become contaminated

- Outdoor control samples may be omitted

- You may incur costs for unneeded or inappropriate samples

Budget constraints will often be a consideration when sampling; professional advice may be necessary to determine if it is possible to take sufficient samples to characterize a problem on a given budget. If it is not possible to sample properly, with a sufficient number of samples to answer the question(s) posed, it would be preferable not to sample. Inadequate sample plans may generate misleading, confusing and useless results.

Keep in mind that air sampling for mold provides information only for the moment in time in which the sampling occurred, much like a snapshot. Air sampling will reveal, when properly done, what was in the air at the moment when the sample was taken. For someone without experience, sampling results will be difficult to interpret. Experience in interpretation of results is essential.

Footnotes:

2. Molds are known allergens and may be toxic. You may wish to use Personal Protective Equipment (PPE) while investigating a mold problem, as well as during remediation/clean-up situations. The minimum PPE includes an N-95 respirator, gloves, and eye protection.

4. Although this document has a residential focus, it is applicable to other building types.

5. Resources List has more information on vapor barriers and building construction. It is important that building materials be able to dry; moisture should not be trapped between two vapor barriers or mold may result. See Resources List

6. Please note that Table 1 and Table 2 contain general guidelines. Their purpose is to provide basic information for remediation managers to first assess the extent of the damage and then to determine whether the remediation should be managed by in-house personnel or outside professionals. The remediation manager can then use the guidelines to help design a remediation plan or to assess a plan submitted by outside professionals. See:

7. Please note that Table 1 and Table 2 contain general guidelines. Their purpose is to provide basic information for remediation managers to first assess the extent of the damage and then to determine whether the remediation should be managed by in-house personnel or outside professionals. The remediation manager can then use the guidelines to help design a remediation plan or to assess a plan submitted by outside professionals. See:

8. Although this document has a residential focus, it is applicable to other building types.

9. If you are unsure what to do, or if the item is expensive or of sentimental value, you may wish to consult a specialist. Specialists commonly listed in phone books include:

- Furniture repair/restoration

- Painting

- Art restoration and conservation

- Carpet and rug cleaning

- Water damage

- Fire/water restoration

Be sure to ask for and check references; look for affiliation with professional organizations. See Resources List.

10. For example, a remediator may decide that a small area that is extensively contaminated and has the potential to distribute mold to occupied areas during cleanup should have full containment, whereas a large wall surface that is lightly contaminated and easily cleaned would require only limited containment.

Table 1: Water Damage - Cleanup and Mold Prevention

Table 1 presents strategies to respond to water damage within 24-48 hours. These guidelines are designed to help avoid the need for remediation of mold growth by taking quick action before growth starts. If mold growth is found on the materials listed in Table 1, refer to Table 2 for guidance on remediation. Depending on the size of the area involved and resources available, professional assistance may be needed to dry an area quickly and thoroughly.

| Water-Damaged Material † | Actions |

|---|---|

| Books and papers |

|

| Carpet and backing - dry within 24-48 hours § |

|

| Ceiling tiles |

|

| Cellulose insulation |

|

| Concrete or cinder block surfaces |

|

| Fiberglass insulation |

|

| Hard surface, porous flooring § (Linoleum, ceramic tile, vinyl) |

|

| Non-porous, hard surfaces |

|

| Upholstered furniture |

|

| Wallboard |

|

| Window drapes |

|

| Wood surfaces |

|

* If mold growth has occurred or materials have been wet for more than 48 hours, consult Table 2 guidelines. Even if materials are dried within 48 hours, mold growth may have occurred. Items may be tested by professionals if there is doubt. Note that mold growth will not always occur after 48 hours; this is only a guideline.

These guidelines are for damage caused by clean water. If you know or suspect that the water source is contaminated with sewage, or chemical or biological pollutants, then Personal Protective Equipment and containment are required by OSHA. An experienced professional should be consulted if you and/or your remediators do not have expertise remediating in contaminated water situations. Do not use fans before determining that the water is clean or sanitary.

† If a particular item(s) has high monetary or sentimental value, you may wish to consult a restoration/water damage specialist.

§ The subfloor under the carpet or other flooring material must also be cleaned and dried. See the appropriate section of this table for recommended actions depending on the composition of the subfloor.

Table 2: Mold Remediation Guidelines

Table 2 presents remediation guidelines for building materials that have or are likely to have mold growth. The guidelines in Table 2 are designed to protect the health of occupants and cleanup personnel during remediation. These guidelines are based on the area and type of material affected by water damage and/or mold growth. Please note that these are guidelines; some professionals may prefer other cleaning methods.

If you are considering cleaning your ducts as part of your remediation plan, you should consult EPA's publication entitled, Should You Have the Air Ducts In Your Home Cleaned? If possible, remediation activities should be scheduled during off-hours when building occupants are less likely to be affected. See:

Although the level of personal protection suggested in these guidelines is based on the total surface area contaminated and the potential for remediator and/or occupant exposure, professional judgment should always play a part in remediation decisions. These remediation guidelines are based on the size of the affected area to make it easier for remediators to select appropriate techniques, not on the basis of health effects or research showing there is a specific method appropriate at a certain number of square feet. The guidelines have been designed to help construct a remediation plan. The remediation manager will then use professional judgment and experience to adapt the guidelines to particular situations. When in doubt, caution is advised. Consult an experienced mold remediator for more information.

A more cautious or conservative approach to remediation is indicated in cases in which:

- A particularly toxic mold species has been identified or is suspected

- When extensive hidden mold is expected (such as behind vinyl wallpaper or in the HVAC system)

- When the chances of the mold becoming airborne are estimated to be high

- Sensitive individuals (e.g., those with severe allergies or asthma) are present

Always make sure to protect remediators and building occupants from exposure to mold.

View details about Cleanup Methods, Personal Protective Equipment and Containment

| Material or Furnishing Affected | Cleanup Methods† | Personal Protective Equipment | Containment |

|---|---|---|---|

| SMALL - Total Surface Area Affected Less Than 10 square feet (ft2) | |||

| Books and papers | 3 | Minimum N-95 respirator, gloves, and goggles |

None required |

| Carpet and backing | 1, 3 | ||

| Concrete or cinder block | 1, 3 | ||

| Hard surface, porous flooring (linoleum, ceramic tile, vinyl) | 1, 2, 3 | ||

| Non-porous, hard surfaces (plastics, metals) | 1, 2, 3 | ||

| Upholstered furniture & drapes | 1, 3 | ||

| Wallboard (drywall and gypsum board) | 3 | ||

| Wood surfaces | 1, 2, 3 | ||

| MEDIUM - Total Surface Area Affected Between 10 and 100 (ft2) | |||

| Books and papers | 3 | Limited or Full Use professional judgment, consider potential for remediator exposure and size of contaminated area |

Limited Use professional judgment, consider potential for remediator/occupant exposure and size of contaminated area |

| Carpet and backing | 1,3,4 | ||

| Concrete or cinder block | 1, 3 | ||

| Hard surface, porous flooring (linoleum, ceramic tile, vinyl) | 1, 2, 3 | ||

| Non-porous, hard surfaces (plastics, metals) | 1, 2, 3 | ||

| Upholstered furniture & drapes | 1,3,4 | ||

| Wallboard (drywall and gypsum board) | 3,4 | ||

| Wood surfaces | 1, 2, 3 | ||

| LARGE - Total Surface Area Affected Greater Than 100 (ft2) or Potential for Increased Occupant or Remediator Exposure During Remediation Estimated to be Significant | |||

| Books and papers | 3 | Full Use professional judgment, consider potential for remediator/occupant exposure and size of contaminated area |

Full Use professional judgment, consider potential for remediator exposure and size of contaminated area |

| Carpet and backing | 1,3,4 | ||

| Concrete or cinder block | 1, 3 | ||

| Hard surface, porous flooring (linoleum, ceramic tile, vinyl) | 1,2,3,4 | ||

| Non-porous, hard surfaces (plastics, metals) | 1, 2, 3 | ||

| Upholstered furniture & drapes | 1,2,4 | ||

| Wallboard (drywall and gypsum board) | 3,4 | ||

| Wood surfaces | 1,2,3,4 | ||

* Use professional judgment to determine prudent levels of Personal Protective Equipment and containment for each situation, particularly as the remediation site size increases and the potential for exposure and health effects rises. Assess the need for increased Personal Protective Equipment, if, during the remediation, more extensive contamination is encountered than was expected. Consult Table 1 if materials have been wet for less than 48 hours, and mold growth is not apparent. These guidelines are for damage caused by clean water. If you know or suspect that the water source is contaminated with sewage, or chemical or biological pollutants, then the Occupational Safety and Health Administration (OSHA) requires PPE and containment. An experienced professional should be consulted if you and/or your remediators do not have expertise in remediating contaminated water situations.

† Select method most appropriate to situation. Since molds gradually destroy the things they grow on, if mold growth is not addressed promptly, some items may be damaged such that cleaning will not restore their original appearance. If mold growth is heavy and items are valuable or important, you may wish to consult a restoration/water damage/remediation expert. Please note that these are guidelines; other cleaning methods may be preferred by some professionals.

Table developed from literature and remediation documents including Bioaerosols: Assessment and Control (American Conference of Governmental Industrial Hygienists, 1999) and IICRC S500, Standard and Reference Guide for Professional Water Damage Restoration, (Institute of Inspection, Cleaning and Restoration, 1999). For more information see Resources List.

Footnotes:

7. Please note that Table 1 and Table 2 contain general guidelines. Their purpose is to provide basic information for remediation managers to first assess the extent of the damage and then to determine whether the remediation should be managed by in-house personnel or outside professionals. The remediation manager can then use the guidelines to help design a remediation plan or to assess a plan submitted by outside professionals. See Table 1

8. Although this document has a residential focus, it is applicable to other building types.

Checklist for Mold Remediation

Investigate and Evaluate Moisture and Mold Problems

Assess size of moldy area (square feet)

Assess size of moldy area (square feet)

Consider the possibility of hidden mold

Consider the possibility of hidden mold

Clean up small mold problems and fix moisture problems before they become large problems

Clean up small mold problems and fix moisture problems before they become large problems

Select remediation manager for medium or large size mold problem

Select remediation manager for medium or large size mold problem

Investigate areas associated with occupant complaints

Investigate areas associated with occupant complaints

Note type of water-damaged materials (wallboard, carpet, etc.)

Note type of water-damaged materials (wallboard, carpet, etc.)

Check inside air ducts and air handling unit

Check inside air ducts and air handling unit

Throughout process, consult qualified professional if necessary or desired

Throughout process, consult qualified professional if necessary or desired

Communicate with Building Occupants at all Stages of Process, as appropriate

Designate contact person for questions and comments about medium or large scale remediation as needed

Designate contact person for questions and comments about medium or large scale remediation as needed

Plan Remediation

Adapt or modify remediation guidelines to fit your situation; use professional judgment

Adapt or modify remediation guidelines to fit your situation; use professional judgment

Plan to dry wet, non-moldy materials within 48 hours to prevent mold growth. See text and Table 1

Plan to dry wet, non-moldy materials within 48 hours to prevent mold growth. See text and Table 1

Select cleanup methods for moldy items. See text and Table 2

Select cleanup methods for moldy items. See text and Table 2

Select Personal Protection Equipment - protect remediators. See text and Table 2

Select Personal Protection Equipment - protect remediators. See text and Table 2

Select containment equipment - protect building, occupants. See text and Table 2

Select containment equipment - protect building, occupants. See text and Table 2

Select remediation personnel who have the experience and training needed to implement the remediation plan and use Personal Protective Equipment and containment as appropriate

Select remediation personnel who have the experience and training needed to implement the remediation plan and use Personal Protective Equipment and containment as appropriate

Remediate Moisture and Mold Problems

Fix moisture problem, implement repair plan and/or maintenance plan

Fix moisture problem, implement repair plan and/or maintenance plan

Dry wet, non-moldy materials within 48 hours to prevent mold growth

Dry wet, non-moldy materials within 48 hours to prevent mold growth

Clean and dry mold materials. See text and Table 2

Clean and dry mold materials. See text and Table 2

Discard moldy porous items that can't be cleaned. See text and Table 2

Discard moldy porous items that can't be cleaned. See text and Table 2

Resources List

- EPA Resources

- Resource List of Public and Private Organizations Dealing with Environmental Exposures

EPA Resources

- An Office Building Occupant's Guide to IAQ

- Biological Contaminants

- Building Air Quality: A Guide for Building Owners and Facility Managers (BAQ Guide)

- Floods/Flooding

- Indoor Air Quality (IAQ) Home Page

- IAQ in Large Buildings/Commercial Buildings

- Creating Healthy Indoor Environments in Schools

Resource List of Public and Private Organizations Dealing with Environmental Exposures

The following list of resources includes information created and maintained by other public and private organizations. The U.S. EPA does not control or guarantee the accuracy, relevance, timeliness, or completeness of this outside information. Further, the inclusion of such resources is not intended to endorse any views expressed or products or services offered by the author of the reference or the organization operating the service on which the reference is maintained.

The following links exit the site Exit

American College of Occupational and Environmental Medicine (ACOEM)

(847) 818-1800

Referrals to physicians who have experience with environmental exposures (this is a members only service).

American Conference of Governmental Industrial Hygienists, Inc. (ACGIH)

(513) 742-2020

Occupational and environmental health and safety information

American Industrial Hygiene Association (AIHA)

(703) 849-8888

American Red Cross

(202) 303-4498

800-REDCROSS

800-257-7575 (Español)

Repairing Your Flooded Home (PDF)(56 pp, 738 K), August 1992

American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. (ASHRAE)

(800) 527-4723

Information on engineering issues and indoor air quality

Association of Occupational and Environmental Clinics (AOEC)

(202) 347-4976

Referrals to clinics with physicians who have experience with environmental exposures, including exposure to mold; maintains a database of occupational and environmental cases.

Asthma and Allergic Diseases:

American Academy of Allergy, Asthma & Immunology (AAAAI)

(800) 822-2762

Physician referral directory, information on allergies and asthma.

Asthma and Allergy Foundation of America (AAFA)

(800) 7-ASTHMA (800-727-8462)

Information on allergies and asthma

American Lung Association (ALA)

(800) LUNG-USA (800-586-4872)

Information on allergies and asthma

Asthma and Allergy Network/Mothers of Asthmatics, Inc. (AAN*MA)

(800) 878-4403 or (703-641-9595)

Information on allergies and asthma

National Institute of Allergy and Infectious Diseases (NIAID)

(301) 496-5717

Information on allergies and asthma.

National Jewish Medical and Research Center

(800) 222-LUNG (800-222-5864)

Information on allergies and asthma

Canada Mortgage and Housing Corporation (CMHC)

(613) 748-2003 [International]

Several documents on mold-related topics available

Carpet and Rug Institute (CRI)

(706) 278-3176

Carpet maintenance, restoration guidelines for water-damaged carpet, other carpet-related issues

Centers for Disease Control and Prevention (CDC)

(800) CDC-INFO (232-4636)

Information on health-related topics including asthma, molds in the environment and occupational health

CDC's National Center for Environmental Health (NCEH)

(800) CDC-INFO (232-4636)

Energy and Environmental Building Association

(952) 881-1098

Information on energy-efficient and environmentally responsible buildings, humidity/moisture control/vapor barriers

Floods/Flooding:

Federal Emergency Management Agency (FEMA)

(800) 621-FEMA (3362)

Flood information

Publications on floods, flood proofing, etc.

University of Minnesota, Department of Environmental Health and Safety

(612) 626-6002

Flood Information

Managing water infiltration into buildings

University of Wisconsin-Extension Disaster Management and Recovery

(608) 262-3980

Information on floods and other natural disasters

Health Canada, Health Protection Branch, Laboratory Centre for Disease Control, Office of Biosafety

(613) 957-1779

Material Safety Data Sheets with health and safety information on infectious microorganisms, including Aspergillus and other molds and airborne biologicals

U.S. Dept. Housing and Urban Development (HUD), Office of Native American Programs

Mold Prevention and Detection: A Guide for Housing Authorities in Indian Country (PDF)(11 pp, 890 K)

Indoor Environmental Remediation Board (IERB)

(916) 736-1100

Information on best practices in building remediation

Institute of Inspection, Cleaning and Restoration Certification (IICRC)

(360) 693-5675

Information on and standards for the inspection, cleaning and restoration industry

Institute of Medicine Report on Damp Indoor Spaces and Health

International Society of Cleaning Technicians (ISCT)

(800) -258-8500

Information on cleaning, such as a stain removal guide for carpets

ISSA - The Worldwide Cleaning Industry Association

(800) 225-4772

Education and training on cleaning and maintenance

National Air Duct Cleaners Association (NADCA)

(202) 737-2926

Duct cleaning information

National Association of the Remodeling Industry (NARI)

(847) 298-9200

Consumer information on remodeling, including help finding a professional remodeling contractor

National Institute of Building Sciences (NIBS)

(202) 289-7800

Information on building regulations, science and technology

National Institute for Occupational Safety and Health (NIOSH)

(800) CDC-INFO (232-4636)

Health and safety information with a workplace orientation

National Pesticide Information Center (NPIC)

(800) 858-7378

Regulatory information, safety information and product information on microbials

The New York City Department of Health and Mental Hygiene

Guidelines on Assessment and Remediation of Fungi in Indoor Environments

Occupational Safety & Health Administration (OSHA)

(800) 321-OSHA (800-321-6742)

OSHA's Mold page

Information on worker safety, including topics such as respirator use and safety in the workplace

The Restoration Industry Association

Phone: (301) 231-6505 / Fax: (301) 231-6569

Disaster recovery, water and fire damage, emergency tips, referrals to professionals. The Water Loss Institute is a membership interest group within the Restoration Industry Association.

Sheet Metal & Air Conditioning Contractors' National Association (SMACNA)

(703) 803-2980

Technical information on topics such as air conditioning and air ducts.

Smithsonian Museum Conservation Institute

(301) 238-1240

Guidelines for caring for and preserving furniture and wooden objects, paper-based materials; preservation studies

University of Michigan Herbarium

(734) 615-6200

Specimen-based information on fungi; information on fungal ecology

University of Tulsa Indoor Air Program

(918) 631-5246

Courses, classes and continuing education on indoor air quality.

Western Wood Products Association

Mold and Wood Products

info@wwpa.org

A trade association representing softwood lumber manufacturers in the 12 Western states.

References

American Academy of Pediatrics, Committee on Environmental Health. "Toxic Effects of Indoor Air Molds." Pediatrics. Volume 101, pp. 712-714. 1996.

American Conference of Governmental Industrial Hygienists. Bioaerosols: Assessment and Control. Macher, J., editor. ACGIH. Cincinnati, OH. ISBN 1-882417-29-1. 1999.

American Conference of Governmental Industrial Hygienists. Guidelines for the Assessment of Bioaerosols in the Indoor Environment. ISBN 0-936712-83-X. 1989.

American Industrial Hygiene Association. Field Guide for the Determination of Biological Contaminants in Environmental Samples. Dillon, H. K., Heinsohn, P. A., and Miller, J. D., editors. Fairfax, VA. 1996.

American Society of Heating, Refrigerating, and Air Conditioning Engineers. Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. ASHRAE Standard 52.2. 2000.

American Society for Microbiology. Manual of Environmental Microbiology. Hurst, C., Editor in Chief. ASM Press. Washington, DC. 1997.

Canada Mortgage and Housing Corporation. Clean-up Procedures for Mold in Houses. ISBN 0-662-21133-2. 1993.

Eastern New York Occupational and Environmental Health Center. Proceedings of the International Conference, Saratoga Springs, NY. October 6-7, 1994. Fungi and Bacteria in Indoor Air Environments - Health Effects, Detection, and Remediation. Johanning, E., and Yang, C., editors. Eastern New York Occupational Health Program. Latham, NY. 1995.

Eastern New York Occupational and Environmental Health Center. Bioaerosols, Fungi and Mycotoxins: Health Effects, Assessment, Prevention and Control.Johanning, E., editor. Albany, NY. 1999. (Proceedings of the Third International Conference on Fungi, Mycotoxins and Bioaerosols: Health Effects, Assessment, Prevention and Control. September 23-25, 1998.)

Gravesen, S., Frisvad, J., and Samson, R. Microfungi. Munksgaard. Copenhagen, Denmark. 1994.

"Indoor Mold and Children's Health." Environmental Health Perspectives, Vol. 107, Suppl. 3, June 1999.

Institute of Inspection, Cleaning and Restoration Certification (IICRC). IICRC S500, Standard and Reference Guide for Professional Water Damage Restoration, 2nd edition 1999.

Lstiburek, J. Building Science Corporation Builder's Guide, Mixed-Humid Climates. Building Science Corporation and the Energy Efficient Building Association. 1999.

National Academy of Sciences, Committee on the Assessment of Asthma and Indoor Air. Clearing the Air: Asthma and Indoor Air Exposures. National Academy Press. 2000.

National Academy of Sciences. Indoor Allergens: Assessing and Controlling Adverse Health Effects. National Academy Press. 1993.

National Institute for Occupational Safety and Health. Guide to the Selection and Use of Particulate Respirators Certified under 42 CFR 84. DHHS (NIOSH) Publication No. 96-101. January 1996.

New York City Department of Health, Bureau of Environmental & Occupational Disease Epidemiology. Guidelines on Assessment and Remediation of Fungi in Indoor Environments. 2000.

Occupational Safety & Health Administration. Respiratory Protection Standard, 29 CFR 1910.134. 63 FR 1152. January 8, 1998.

U.S. Environmental Protection Agency. Should You Have the Air Ducts In Your Home Cleaned? EPA-402-K-97-002.

U.S. Environmental Protection Agency. IAQ Tools for Schools Action Kit EPA 402-K-07-008.

Introduction to Molds (Appendix B)

- Molds in the Environment

- Health Effects and Symptoms Associated with Mold Exposure

- Mold Toxins (Mycotoxins)

- Microbial Volatile Organic Compounds (mVOCs)

- Glucans or Fungal Cell Wall Components

- Spores

Molds in the Environment

Molds live in the soil, on plants and on dead or decaying matter. Outdoors, molds play a key role in the breakdown of leaves, wood and other plant debris. Molds belong to the kingdom Fungi, and unlike plants, they lack chlorophyll and must survive by digesting plant materials, using plant and other organic materials for food. Without molds, our environment would be overwhelmed with large amounts of dead plant matter.

Molds produce tiny spores to reproduce, just as some plants produce seeds. These mold spores can be found in both indoor and outdoor air, and settled on indoor and outdoor surfaces. When mold spores land on a damp spot, they may begin growing and digesting whatever they are growing on in order to survive. Since molds gradually destroy the things they grow on, you can prevent damage to building materials and furnishings and save money by eliminating mold growth.

Moisture control is the key to mold control. Molds need both food and water to survive; since molds can digest most things, water is the factor that limits mold growth. Molds will often grow in damp or wet areas indoors. Common sites for indoor mold growth include

- Bathroom tile

- Basement walls

- Areas around windows where moisture condenses

- Near leaky water fountains or sinks

Common sources or causes of water or moisture problems include:

- Roof leaks

- Deferred maintenance

- Condensation associated with high humidity or cold spots in the building

- Localized flooding due to:

- Plumbing failures or heavy rains

- Slow leaks in plumbing fixtures

- Malfunction or poor design of humidification systems

- Uncontrolled humidity can also be a source of moisture leading to mold growth, particularly in hot, humid climates.

Health Effects and Symptoms Associated with Mold Exposure

When moisture problems occur and mold growth results, building occupants may begin to report odors and a variety of health problems, such as:

- Headaches

- Breathing difficulties

- Skin irritation

- Allergic reactions

- Aggravation of asthma symptoms

All of these symptoms could potentially be associated with mold exposure.

All molds have the potential to cause health effects. Molds produce allergens, irritants, and in some cases, toxins that may cause reactions in humans. The types and severity of symptoms depend, in part, on:

- The types of mold present

- The extent of an individual's exposure

- The ages of the individuals

- Their existing sensitivities or allergies

Specific reactions to mold growth can include the following:

Allergic Reactions

Inhaling or touching mold or mold spores may cause allergic reactions in sensitive individuals. Allergic reactions to mold are common - these reactions can be immediate or delayed. Allergic responses include hay fever-type symptoms, such as:

- Sneezing

- Runny nose

- Red eyes

- Skin rash (dermatitis)

Mold spores and fragments can produce allergic reactions in sensitive individuals regardless of whether the mold is dead or alive. Repeated or single exposure to mold or mold spores may cause previously non-sensitive individuals to become sensitive. Repeated exposure has the potential to increase sensitivity.

Asthma

Molds can trigger asthma attacks in persons who are allergic (sensitized) to molds. The irritants produced by molds may also worsen asthma in non-allergic (non-sensitized) people.

Hypersensitivity Pneumonitis

Hypersensitivity pneumonitis may develop following either short-term (acute) or long-term (chronic) exposure to molds. The disease resembles bacterial pneumonia and is uncommon.

Irritant Effects

Mold exposure can cause irritation of the eyes, skin, nose, throat, and lungs, and sometimes, it can also create a burning sensation in these areas.

Opportunistic Infections

People with weakened immune systems (i.e., immune-compromised or immune-suppressed individuals) may be more vulnerable to infections by molds (as well as more vulnerable than healthy persons to mold toxins). Aspergillus fumigatus, for example, has been known to infect the lungs of immune-compromised individuals. These individuals inhale the mold spores which then start growing in their lungs. Trichoderma has also been known to infect immune-compromised children.

Healthy individuals are usually not vulnerable to opportunistic infections from airborne mold exposure. However, molds can cause common skin diseases, such as athlete's foot, as well as other infections such as yeast infections.

Mold Toxins (Mycotoxins)

Molds can produce toxic substances called mycotoxins. Some mycotoxins cling to the surface of mold spores; others may be found within spores. More than 200 mycotoxins have been identified from common molds, and many more remain to be identified. Some of the molds that are known to produce mycotoxins are commonly found in moisture-damaged buildings. Exposure pathways for mycotoxins can include:

- Inhalation

- Ingestion

- Skin contact

Although some mycotoxins are well known to affect humans and have been shown to be responsible for human health effects, for many mycotoxins, little information is available.

Aflatoxin B1 is perhaps the most well known and studied mycotoxin. It can be produced by the molds Aspergillus flavus and Aspergillus parasiticus and is one of the most potent carcinogens known. Ingestion of aflatoxin B1 can cause liver cancer. There is also some evidence that inhalation of aflatoxin B1 can cause lung cancer. Aflatoxin B1 has been found on contaminated grains, peanuts and other human and animal foodstuffs. However, Aspergillus flavus and Aspergillus parasiticus are not commonly found on building materials or in indoor environments.

Much of the information on the human health effects of inhalation exposure to mycotoxins comes from studies done in the workplace and some case studies or case reports.

* Many symptoms and human health effects attributed to inhalation of mycotoxins have been reported including:

- Mucous membrane irritation

- Skin rash

- Nausea

- Immune system suppression

- Acute or chronic liver damage

- Acute or chronic central nervous system damage

- Endocrine effects

- Cancer

More studies are needed to get a clear picture of the health effects related to most mycotoxins. However, it is clearly prudent to avoid exposure to molds and mycotoxins.

Some molds can produce several toxins, and some molds produce mycotoxins only under certain environmental conditions. The presence of mold in a building does not necessarily mean that mycotoxins are present or that they are present in large quantities.

Note: Information on ingestion exposure, for both humans and animals, is more abundant — wide range of health effects has been reported following ingestion of moldy foods including liver damage, nervous system damage and immunological effects.

Microbial Volatile Organic Compounds (mVOCs)

Some compounds produced by molds are volatile and are released directly into the air. These are known as microbial volatile organic compounds (mVOCs). Because these compounds often have strong and/or unpleasant odors, they can be the source of odors associated with molds. Exposure to mVOCs from molds has been linked to symptoms such as:

- Headaches

- Nasal irritation

- Dizziness

- Fatigue

- Nausea

Research on MVOCs is still in the early phase.

Glucans or Fungal Cell Wall Components (also known as β-(1-)-D-Glucans)

Glucans are small pieces of the cell walls of molds which may cause inflammatory lung and airway reactions. These glucans can affect the immune system when inhaled. Exposure to very high levels of glucans or dust mixtures including glucans may cause a flu-like illness known as Organic Dust Toxic Syndrome (ODTS). This illness has been primarily noted in agricultural and manufacturing settings.

Spores

Mold spores are microscopic (2-10 u m) and are naturally present in both indoor and outdoor air. Molds reproduce by means of spores. Some molds have spores that are easily disturbed and waft into the air and settle repeatedly with each disturbance. Other molds have sticky spores that will cling to surfaces and are dislodged by brushing against them or by other direct contact. Spores may remain able to grow for years after they are produced. In addition, whether or not the spores are alive, the allergens in and on them may remain allergenic for years.

Communicating with Building Occupants (Appendix C)

Communication with building occupants is essential for successful mold remediation. Some occupants will naturally be concerned about mold growth in their building and the potential health impacts. Occupants' perceptions of the health risk may rise if they perceive that information is being withheld from them. The status of the building investigation and remediation should be openly communicated including information on any known or suspected health risks.

Small remediation efforts will usually not require a formal communication process, but do be sure to take individual concerns seriously and use common sense when deciding whether formal communications are required. Individuals managing medium or large remediation efforts should make sure they understand and address the concerns of building occupants and communicate clearly what has to be done as well as possible health concerns.

Communication approaches include regular memos and/or meetings with occupants (with time allotted for questions and answers), depending on the scope of the remediation and the level of occupant interest. Tell the occupants about the size of the project, planned activities and remediation timetable. Send or post regular updates on the remediation progress, and send or post a final memo when the project is completed or hold a final meeting.

Try and resolve issues and occupant concerns as they come up. When building-wide communications are frequent and open, those managing the remediation can direct more time toward resolving the problem and less time to responding to occupant concerns.

If possible, remediation activities should be scheduled during off-hours when building occupants are less likely to be affected. Communication is important if occupants are relocated during remediation. The decision to relocate occupants should consider:

- The size of the area affected

- The extent and types of health effects exhibited by the occupants

- The potential health risks associated with debris and activities during the remediation project

When considering the issue of relocation, be sure to inquire about, accommodate and plan for individuals with:

- Asthma

- Allergies

- Compromised immune systems

- Other health-related concerns

Smooth the relocation process and give occupants an opportunity to participate in resolution of the problem by clearly explaining the disruption of the workplace and work schedules. Notify individuals of relocation efforts in advance, if possible.

Acknowledgements

This document was prepared by the Indoor Environments Division (IED) of the U.S. Environmental Protection Agency. IED would like to thank the reviewers of this document who provided many valuable and insightful comments, and the contractors who provided support during the development of this document.

EPA would also like to thank those who provided photos:

- Terry Brennan

- Paul Ellringer

- Stephen Vesper, Ph.D.

- Chin Yang, Ph.D.

Please note that this document presents recommendations on mold remediation. EPA does not regulate mold or mold spores in indoor air.